| Secciones |

|---|

| Foros Electrónica |

|

|

| Boletines de correo |

|

© 2004 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice.

Doc. No. 1088, Rev. M

HA

LOGEN FREE

TM

LEAD FREE

CS

SK

DI

DO

VCC

NC

ORG

GND

1

2

3

4

8

7

6

5

CS

SK

DI

DO

VCC

ORG

GND

1

2

3

4

8

7

6

5

VCC

CS

SK

ORG

GND

DO

DI

1

2

3

4

8

7

6

5

CS

SK

DI

DO

VCC

ORG

GND

1

2

3

4

8

7

6

5

NC

NC

NC

1

2

3

4

8

7

6

5

VCC

NC

ORG

GND

CS

SK

DI

DO

8

7

6

5

VCC

ORG

GND

DI

CS

SK

DO

1

2

3

4

NC

CAT93C56/57

(Die Rev. E)

2K-Bit Microwire Serial EEPROM

FEATURES

•–

High speed operation: 1MHz

•–

Low power CMOS technology

•–

1.8 to 6.0 volt operation

•–

Selectable x8 or x16 memory organization

•–

Self-timed write cycle with auto-clear

•–

Hardware and software write protection

•–

Power-up inadvertant write protection

•–

1,000,000 Program/erase cycles

•–

100 year data retention

•–

Commercial, industrial and automotive

temperature ranges

•–

Sequential read

•–

†śGreen†ť package option available

PIN CONFIGURATION

DIP Package (P, L)

SOIC Package (J,W)

using Catalyst’s advanced CMOS EEPROM floating

gate technology. The devices are designed to endure

1,000,000 program/erase cycles and has a data reten-

tion of 100 years. The devices are available in 8-pin DIP,

8-pin SOIC, 8-pin TSSOP and 8-pad TDFN packages.

DESCRIPTION

The CAT93C56/57 are 2K-bit Serial EEPROM memory

devices which are configured as either registers of 16

bits (ORG pin at V

CC

) or 8 bits (ORG pin at GND). Each

register can be written (or read) serially by using the

DI (or DO) pin. The CAT93C56/57 are manufactured

SOIC Package (S,V)

SOIC Package (K,X)

TSSOP Package (U,Y)

TDFN Package (RD4, ZD4)

Bottom View

FUNCTIONAL SYMBOL

Note: When the ORG pin is connected to VCC, the x16 organiza-

tion is selected. When it is connected to ground, the x8 pin is

selected. If the ORG pin is left unconnected, then an internal pullup

device will select the x16 organization.

CS

SK

NC

ORG

DO

DI

V

CC

GND

PIN FUNCTIONS

Pin Name

Function

CS

Chip Select

SK

Clock Input

DI

Serial Data Input

DO

Serial Data Output

V

CC

+1.8 to 6.0V Power Supply

GND

Ground

ORG

Memory Organization

NC

No Connection

2

CAT93C56/57

Doc. No. 1088, Rev. M

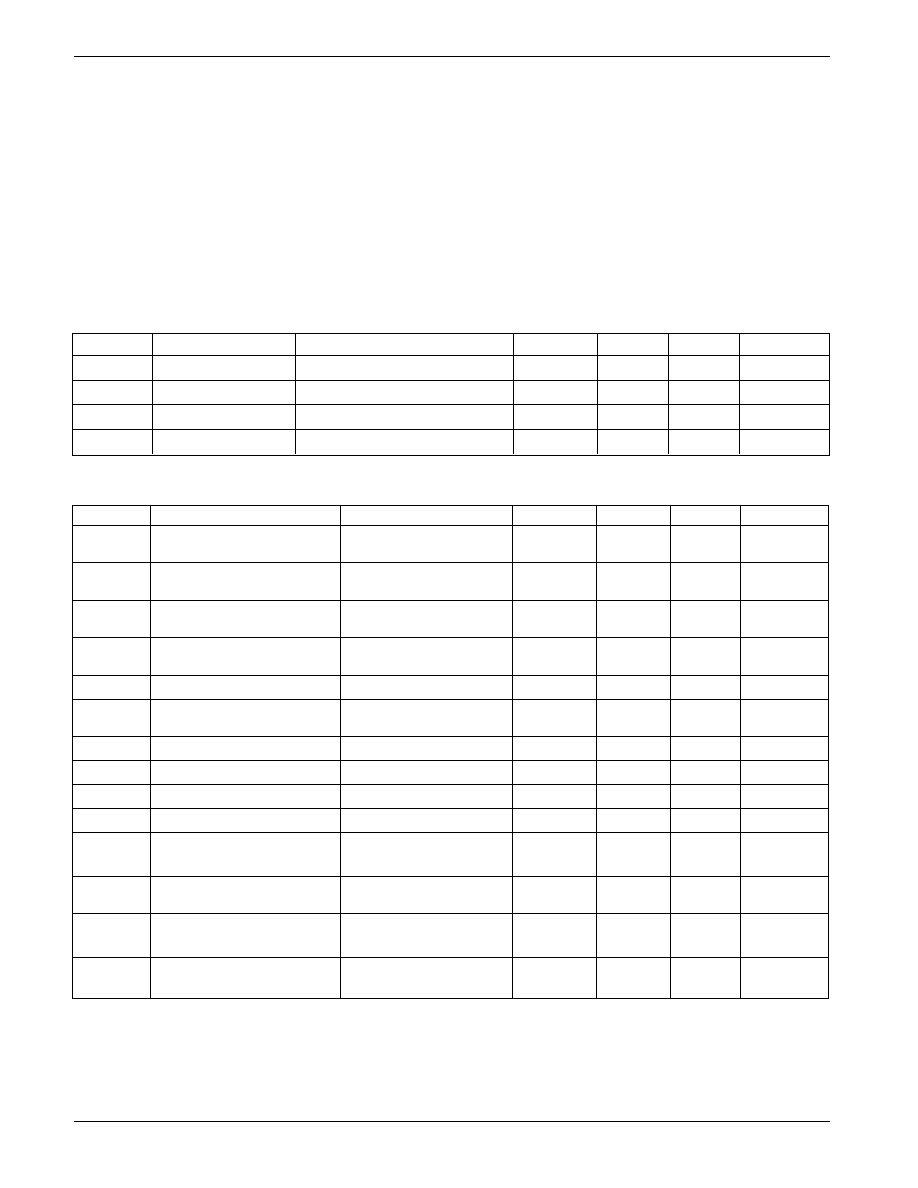

D.C. OPERATING CHARACTERISTICS

V

CC

= +1.8V to +6.0V, unless otherwise specified.

SymbolParameter

Test Conditions

Min

Typ

Max

Units

I

CC1

Power Supply Current

f

SK

= 1MHz

3

mA

(Write)

V

CC

= 5.0V

I

CC2

Power Supply Current

f

SK

= 1MHz

500

µA

(Read)

V

CC

= 5.0V

I

SB1

Power Supply Current

CS = 0V

10

µA

(Standby) (x8 Mode)

ORG=GND

I

SB2

Power Supply Current

CS=0V

0

10

µA

(Standby) (x16Mode)

ORG=Float or V

CC

I

LI

Input Leakage Current

V

IN

= 0V to V

CC

1

µA

I

LO

Output Leakage Current

V

OUT

= 0V to V

CC

,

1

µA

(Including ORG pin)

CS = 0V

V

IL1

Input Low Voltage

4.5V

≤ V

CC

< 5.5V

-0.1

0.8

V

V

IH1

Input High Voltage

4.5V

≤ V

CC

< 5.5V

2

V

CC

+ 1

V

V

IL2

Input Low Voltage

1.8V

≤ V

CC

< 4.5V

0

V

CC

x 0.2

V

V

IH2

Input High Voltage

1.8V

≤ V

CC

< 4.5V

V

CC

x 0.7

V

CC

+1

V

V

OL1

Output Low Voltage

4.5V

≤ V

CC

< 5.5V

0.4

V

I

OL

= 2.1mA

V

OH1

Output High Voltage

4.5V

≤ V

CC

< 5.5V

2.4

V

I

OH

= -400

µA

V

OL2

Output Low Voltage

1.8V

≤ V

CC

< 4.5V

0.2

V

I

OL

= 1mA

V

OH2

Output High Voltage

1.8V

≤ V

CC

< 4.5V

V

CC

- 0.2

V

I

OH

= -100

µA

ABSOLUTE MAXIMUM RATINGS*

Temperature Under Bias .................. -55

°C to +125 °C

Storage Temperature ........................ -65

°C to +150 °C

Voltage on any Pin with

Respect to Ground

(1)

............. -2.0V to +V

CC

+2.0V

V

CC

with Respect to Ground ................ -2.0V to +7.0V

Package Power Dissipation

Capability (T

A

= 25

°C) ................................... 1.0W

Lead Soldering Temperature (10 secs) ............ 300

°C

Output Short Circuit Current

(2)

........................ 100 mA

*COMMENT

Stresses above those listed under †śAbsolute Maximum

Ratings†ť may cause permanent damage to the device.

These are stress ratings only, and functional operation of

the device at these or any other conditions outside of those

listed in the operational sections of this specification is not

implied. Exposure to any absolute maximum rating for

extended periods may affect device performance and

reliability.

RELIABILITY CHARACTERISTICS

SymbolParameter

Reference Test Method

Min

Typ

Max

Units

N

END

(3)

Endurance

MIL-STD-883, Test Method 1033

1,000,000

Cycles/Byte

T

DR

(3)

Data Retention

MIL-STD-883, Test Method 1008

100

Years

V

ZAP

(3)

ESD Susceptibility

MIL-STD-883, Test Method 3015

2000

Volts

I

LTH

(3)(4)

Latch-Up

JEDEC Standard 17

100

mA

Note:

(1) The minimum DC input voltage is -0.5V. During transitions, inputs may undershoot to -2.0V for periods of less than 20 ns. Maximum DC

voltage on output pins is V

CC

+0.5V, which may overshoot to V

CC

+2.0V for periods of less than 20 ns.

(2) Output shorted for no more than one second. No more than one output shorted at a time.

(3) This parameter is tested initially and after a design or process change that affects the parameter.

(4) Latch-up protection is provided for stresses up to 100 mA on address and data pins from -1V to V

CC

+1V.

3

CAT93C56/57

Doc. No. 1088, Rev. M

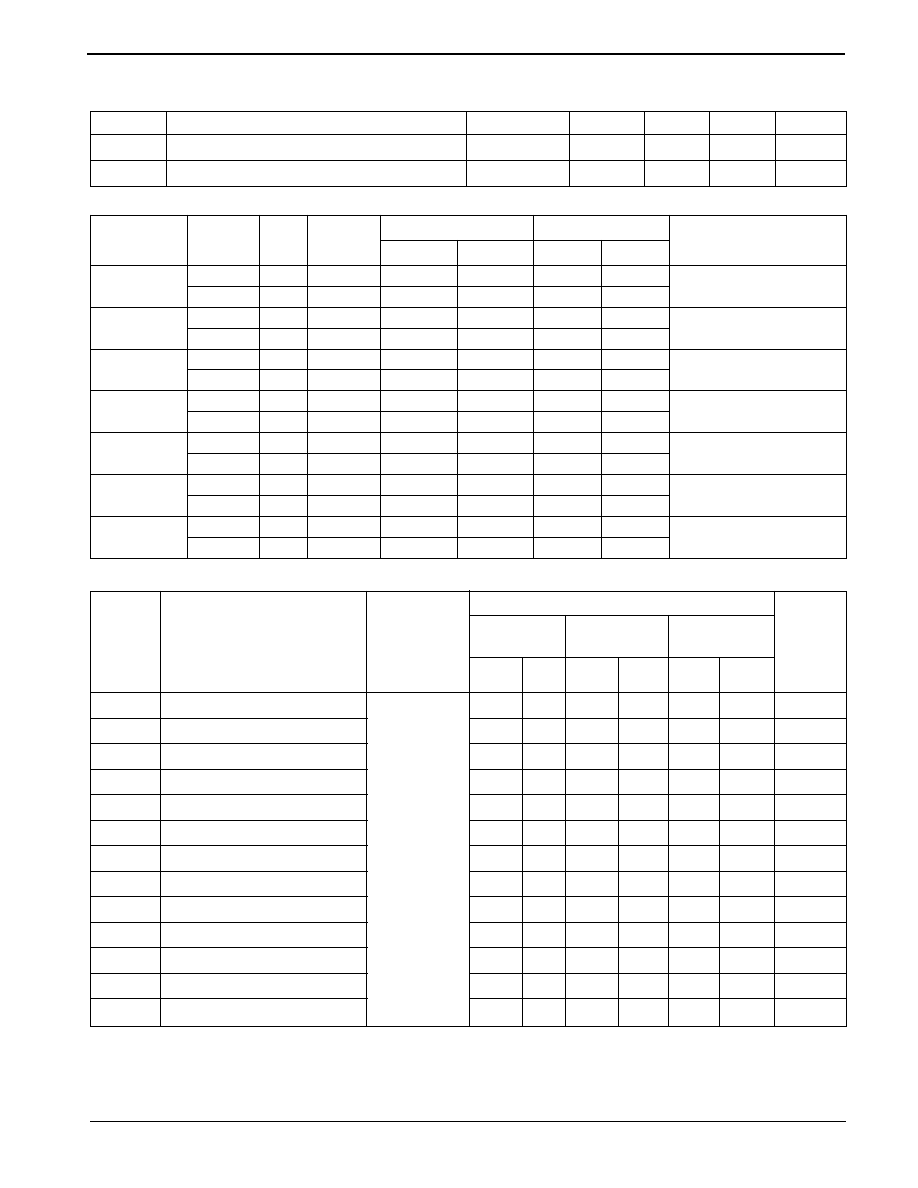

PIN CAPACITANCE

SymbolTest

Conditions

Min

Typ

Max

Units

C

OUT

(2)

Output Capacitance (DO)

V

OUT

=0V

5

pF

C

IN

(2)

Input Capacitance (CS, SK, DI, ORG)

V

IN

=0V

5

pF

INSTRUCTION SET

n

o

i

t

c

u

r

t

s

n

I

e

c

i

v

e

D

e

p

y

T

t

r

a

t

S

t

i

B

e

d

o

c

p

O

s

s

e

r

d

d

A

a

t

a

D

s

t

n

e

m

m

o

C

8

x

6

1

x

8

x

6

1

x

D

A

E

R

6

5

C

3

9

)

1

(

1

0

1

0

A

-

8

A

0

A

-

7

A

0

A

-

N

A

s

s

e

r

d

d

A

d

a

e

R

7

5

C

3

9

1

0

1

0

A

-

7

A

0

A

-

6

A

E

S

A

R

E

6

5

C

3

9

)

1

(

1

1

1

0

A

-

8

A

0

A

-

7

A

0

A

-

N

A

s

s

e

r

d

d

A

r

a

e

l

C

7

5

C

3

9

1

1

1

0

A

-

7

A

0

A

-

6

A

E

T

I

R

W

6

5

C

3

9

)

1

(

1

1

0

0

A

-

8

A

0

A

-

7

A

0

D

-

7

D

0

D

-

5

1

D

0

A

-

N

A

s

s

e

r

d

d

A

e

t

i

r

W

7

5

C

3

9

1

1

0

0

A

-

7

A

0

A

-

6

A

0

D

-

7

D

0

D

-

5

1

D

N

E

W

E

6

5

C

3

9

)

1

(

1

0

0

X

X

X

X

X

1

1

X

X

X

X

X

X

X

1

1

X

e

l

b

a

n

E

e

t

i

r

W

7

5

C

3

9

1

0

0

X

X

X

X

X

1

1

X

X

X

X

X

X

1

1

S

D

W

E

6

5

C

3

9

)

1

(

1

0

0

0

0

X

X

X

X

X

X

X

0

0

X

X

X

X

X

X

e

l

b

a

s

i

D

e

t

i

r

W

7

5

C

3

9

1

0

0

0

0

X

X

X

X

X

X

0

0

X

X

X

X

X

L

A

R

E

6

5

C

3

9

)

1

(

1

0

0

10

X

X

X

X

X

X

X

10

X

X

X

X

X

X

s

e

s

s

e

r

d

d

A

ll

A

r

a

e

l

C

7

5

C

3

9

1

0

0

10

X

X

X

X

X

X

10

X

X

X

X

X

L

A

R

W

6

5

C

3

9

)

1

(

1

0

0

0

X

X

X

X

X

1

X

X

0

X

X

X

X

X

1

X

0

D

-

7

D

0

D

-

5

1

D

s

e

s

s

e

r

d

d

A

ll

A

e

t

i

r

W

7

5

C

3

9

1

0

0

0

X

X

X

X

X

1

X

0

X

X

X

X

X

1

0

D

-

7

D

0

D

-

5

1

D

Limits

V

CC

=

V

CC

=

V

CC

=

1.8V-6V

2.5V-6V

4.5V-5.5V

Test

SymbolParameter

Conditions

Min

Max

Min

Max

Min

Max

Units

t

CSS

CS Setup Time

200

100

50

ns

t

CSH

CS Hold Time

0

0

0

ns

t

DIS

DI Setup Time

400

200

100

ns

t

DIH

DI Hold Time

400

200

100

ns

t

PD1

Output Delay to 1

1

0.5

0.25

µs

t

PD0

Output Delay to 0

1

0.5

0.25

µs

t

HZ

(1)

Output Delay to High-Z

400

200

100

ns

t

EW

Program/Erase Pulse Width

10

10

10

ms

t

CSMIN

Minimum CS Low Time

1

0.5

0.25

µs

t

SKHI

Minimum SK High Time

1

0.5

0.25

µs

t

SKLOW

Minimum SK Low Time

1

0.5

0.25

µs

t

SV

Output Delay to Status Valid

1

0.5

0.25

µs

SK

MAX

Maximum Clock Frequency

DC

250

DC

500

DC

1000

kHz

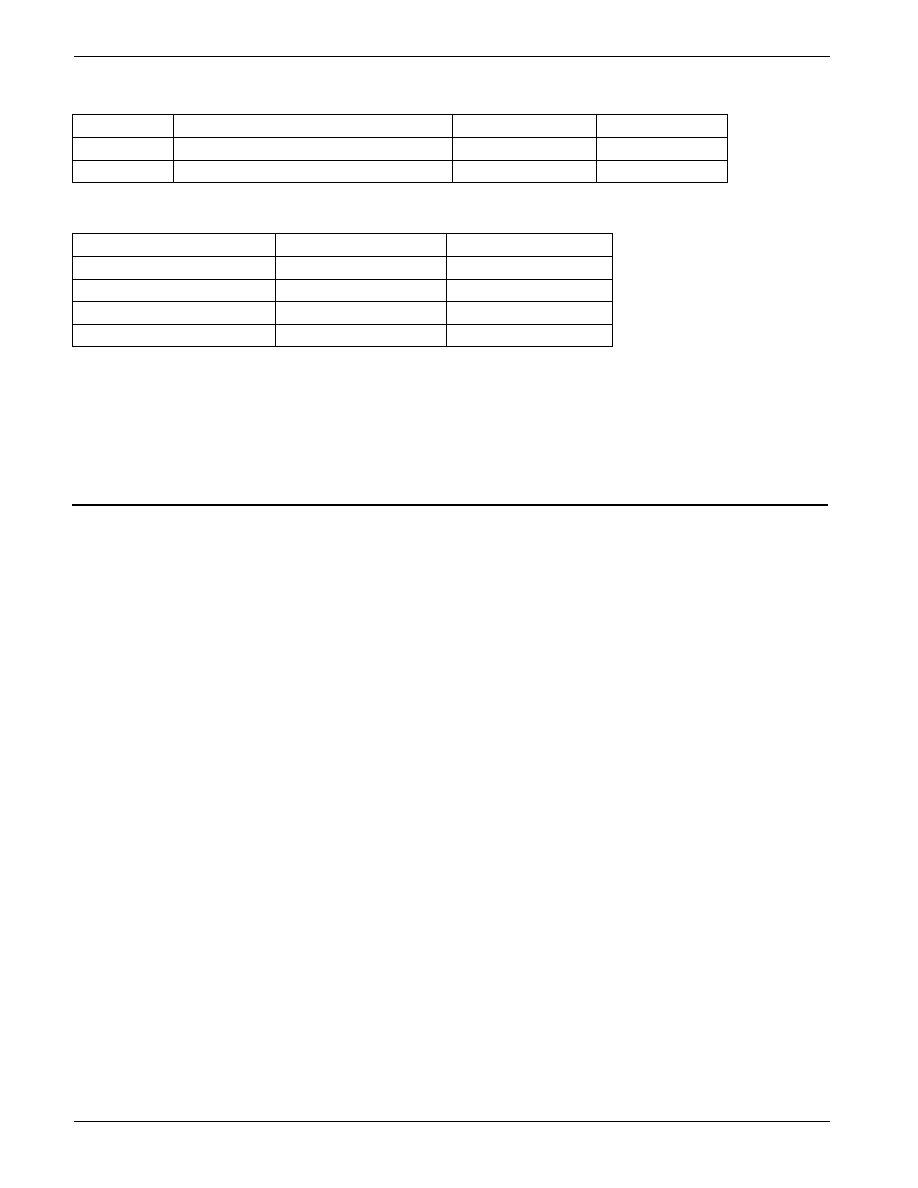

A.C. CHARACTERISTICS

C

L

= 100pF

(3)

Note:

(1)

Address bit A8 for 256x8 ORG and A7 for 128x16 ORG are "Don't Care" bits, but must be kept at either a "1" or "0" for READ, WRITE

and ERASE commands.

(2)

This parameter is tested initially and after a design or process change that affects the parameter.

4

CAT93C56/57

Doc. No. 1088, Rev. M

A.C. TEST CONDITIONS

Input Rise and Fall Times

≤ 50ns

Input Pulse Voltages

0.4V to 2.4V

4.5V

≤ V

CC

≤ 5.5V

Timing Reference Voltages

0.8V, 2.0V

4.5V

≤ V

CC

≤ 5.5V

Input Pulse Voltages

0.2V

CC

to 0.7V

CC

1.8V

≤ V

CC

≤ 4.5V

Timing Reference Voltages

0.5V

CC

1.8V

≤ V

CC

≤ 4.5V

POWER-UP TIMING

(1)(2)

SymbolParameter

Max

Units

t

PUR

Power-up to Read Operation

1

ms

t

PUW

Power-up to Write Operation

1

ms

NOTE:

(1) This parameter is tested initially and after a design or process change that affects the parameter.

(2) t

PUR

and t

PUW

are the delays required from the time V

CC

is stable until the specified operation can be initiated.

(3) The input levels and timing reference points are shown in †śAC Test Conditions†ť table.

DEVICE OPERATION

The CAT93C56/57 is a 2048-bit nonvolatile memory

intended for use with industry standard microproces-

sors. The CAT93C56/57 can be organized as either

registers of 16 bits or 8 bits. When organized as X16,

seven 10-bit instructions for 93C57; seven 11-bit

instructions for 93C56 control the reading, writing and

erase operations of the device. When organized as X8,

seven 11-bit instructions for 93C57; seven 12-bit in-

structions for 93C56 control the reading, writing and

erase operations of the device. The CAT93C56/57

operates on a single power supply and will generate

on chip, the high voltage required during any write

operation.

Instructions, addresses, and write data are clocked into

the DI pin on the rising edge of the clock (SK). The DO

pin is normally in a high impedance state except when

reading data from the device, or when checking the

ready/busy status after a write operation.

The ready/busy status can be determined after the start

of a write operation by selecting the device (CS high)

and polling the DO pin; DO low indicates that the

write operation is not completed, while DO high indi-

cates that the device is ready for the next instruction. If

necessary, the DO pin may be placed back into a high

impedance state during chip select by shifting a dummy

†ś1†ť into the DI pin. The DO pin will enter the high

impedance state on the falling edge of the clock (SK).

Placing the DO pin into the high impedance state is

recommended in applications where the DI pin and the

DO pin are to be tied together to form a common DI/O

pin.

The format for all instructions sent to the device is a

logical "1" start bit, a 2-bit (or 4-bit) opcode, 7-bit address

(93C57)/ 8-bit address (93C56) (an additional bit when

organized X8) and for write operations a 16-bit data field

(8-bit for X8 organizations).

Read

Upon receiving a READ command and an address

(clocked into the DI pin), the DO pin of the CAT93C56/

57 will come out of the high impedance state and, after

sending an initial dummy zero bit, will begin shifting out

the data addressed (MSB first). The output data bits will

toggle on the rising edge of the SK clock and are stable

after the specified time delay (t

PD0

or t

PD1

).

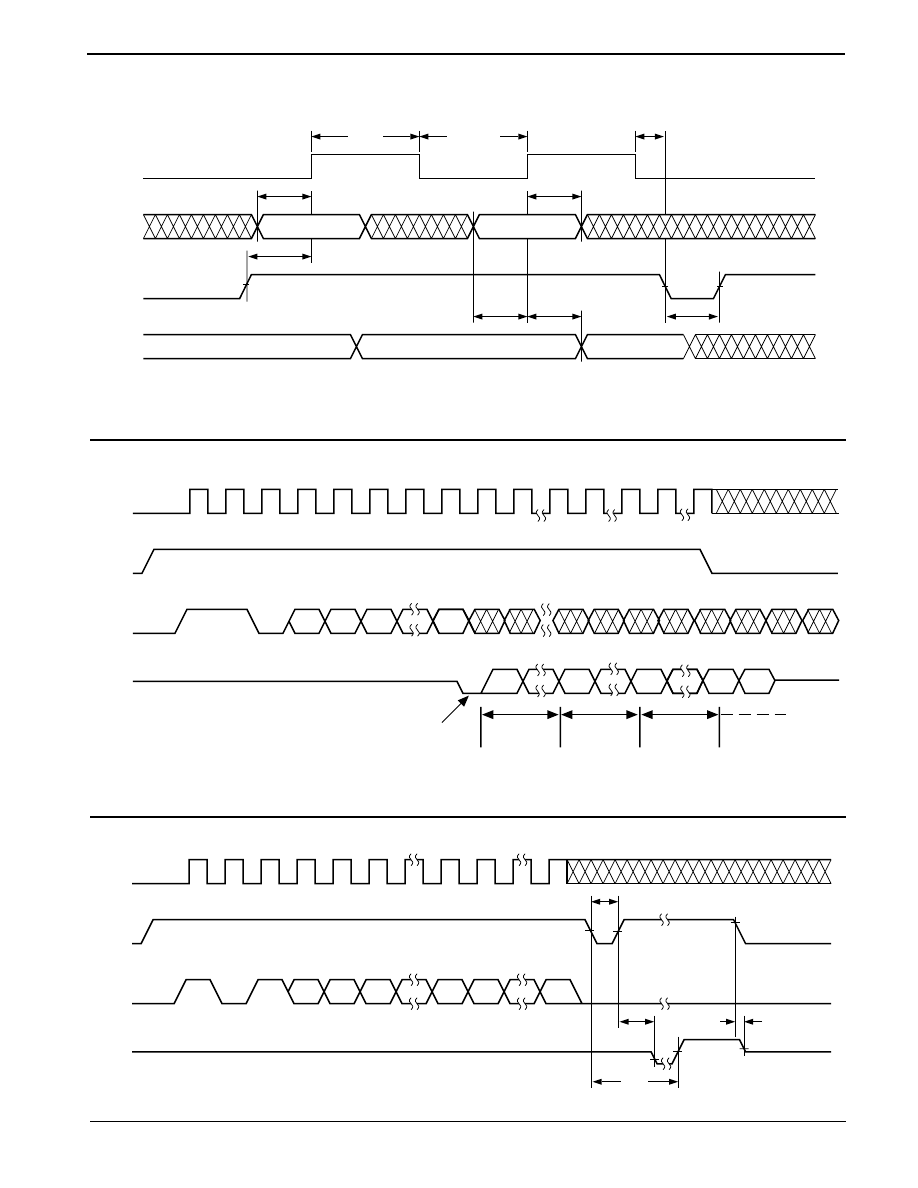

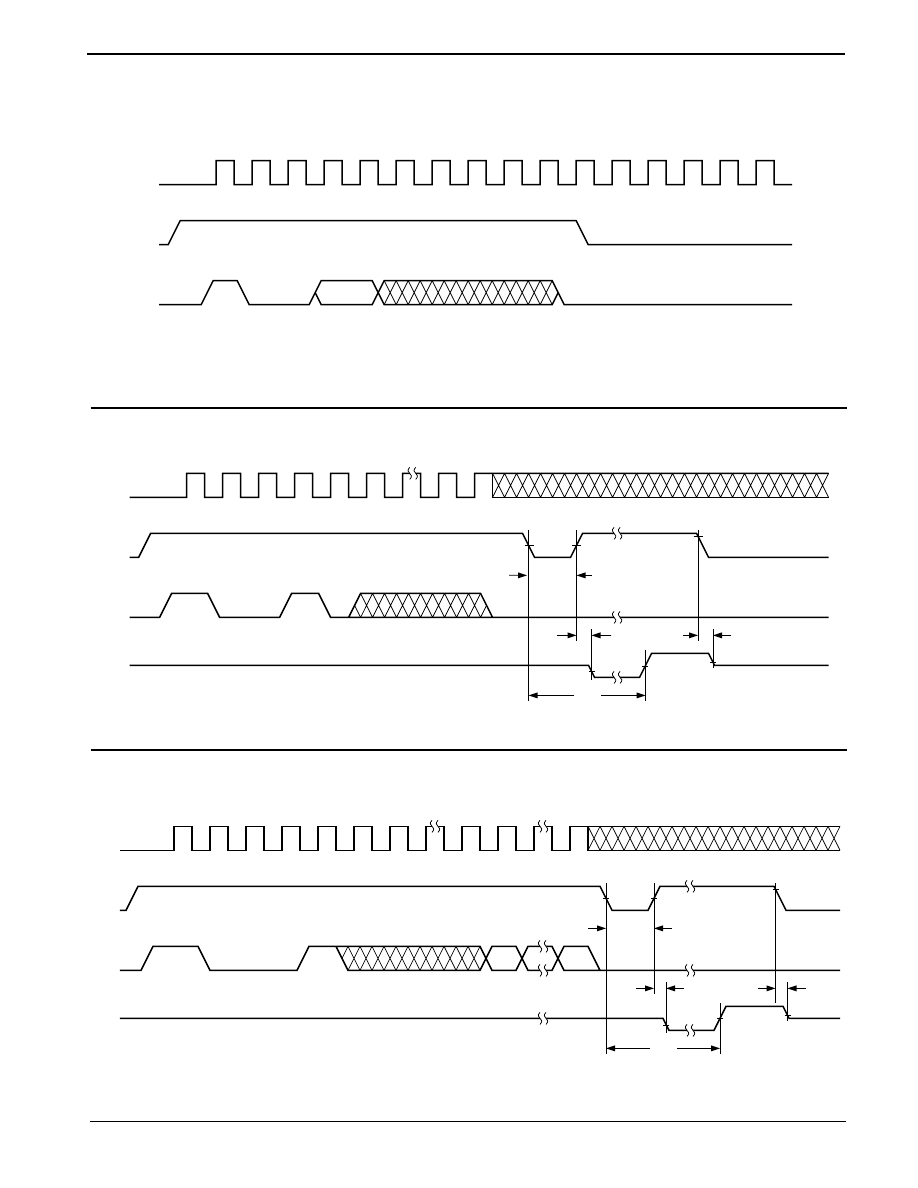

Write

After receiving a WRITE command, address and the

data, the CS (Chip Select) pin must be deselected for a

minimum of t

CSMIN

. The falling edge of CS will start the

self clocking clear and data store cycle of the memory

location specified in the instruction. The clocking of the

SK pin is not necessary after the device has entered the

self clocking mode. The ready/busy status of the

CAT93C56/57 can be determined by selecting the device

and polling the DO pin. Since this device features Auto-

Clear before write, it is NOT necessary to erase a

memory location before it is written into.

5

CAT93C56/57

Doc. No. 1088, Rev. M

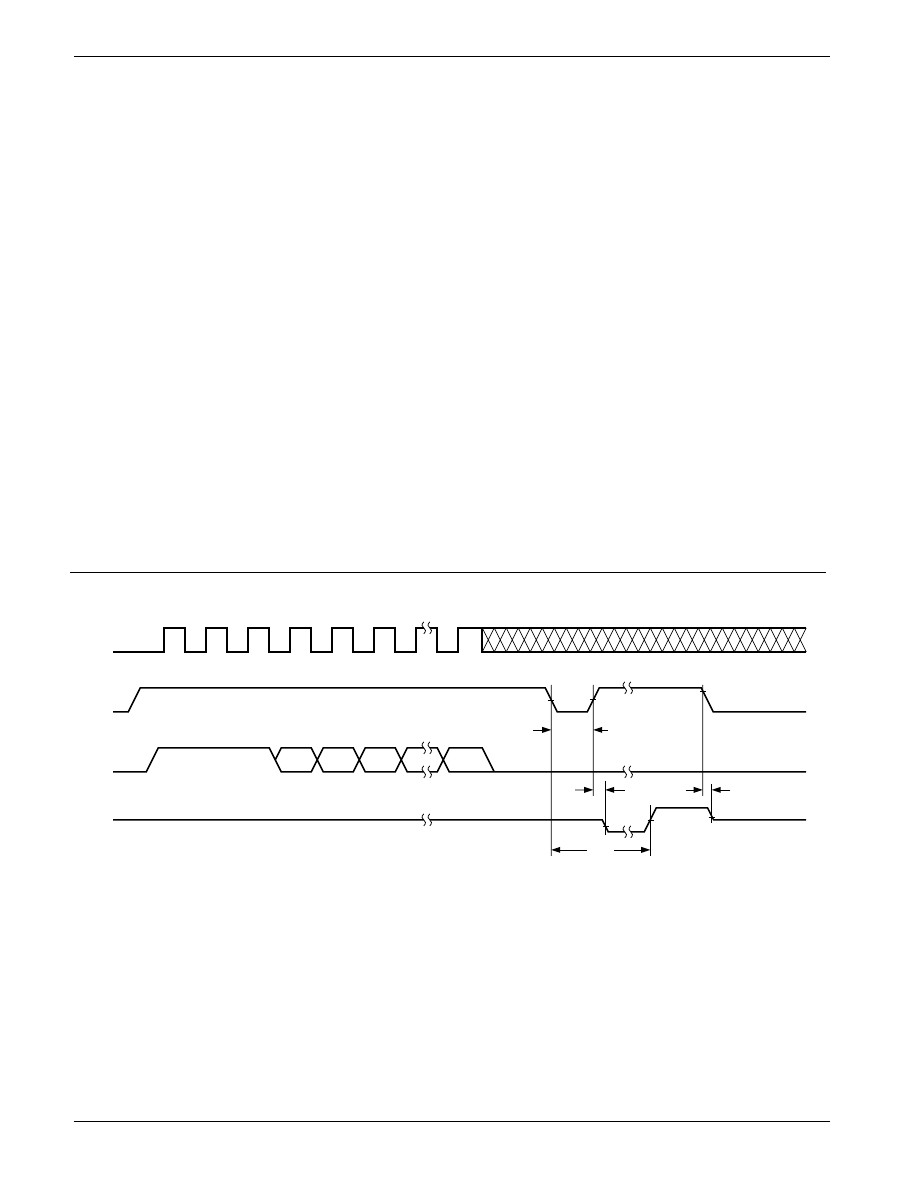

Figure 1. Sychronous Data Timing

Figure 2. Read Instruction Timing

SK

DI

CS

DO

tDIS

tPD0,tPD1

tCSMIN

tCSS

tDIS

tDIH

tSKHI

tCSH

VALID

VALID

DATA VALID

tSKLOW

SK

CS

DI

DO

HIGH-Z

1

1

0

AN AN-1

A0

Dummy 0

D15 . . . D0

or

D7 . . . D0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Address + 1

D15 . . . D0

or

D7 . . . D0

Address + 2

D15 . . . D0

or

D7 . . . D0

Address + n

D15 . . .

or

D7 . . .

Don't Care

Figure 3. Write Instruction Timing

SK

CS

DI

DO

tCSMIN

STANDBY

HIGH-Z

HIGH-Z

1

0

1

AN AN-1

A0

DN

D0

BUSY

READY

STATUS

VERIFY

tSV

tHZ

tEW

6

CAT93C56/57

Doc. No. 1088, Rev. M

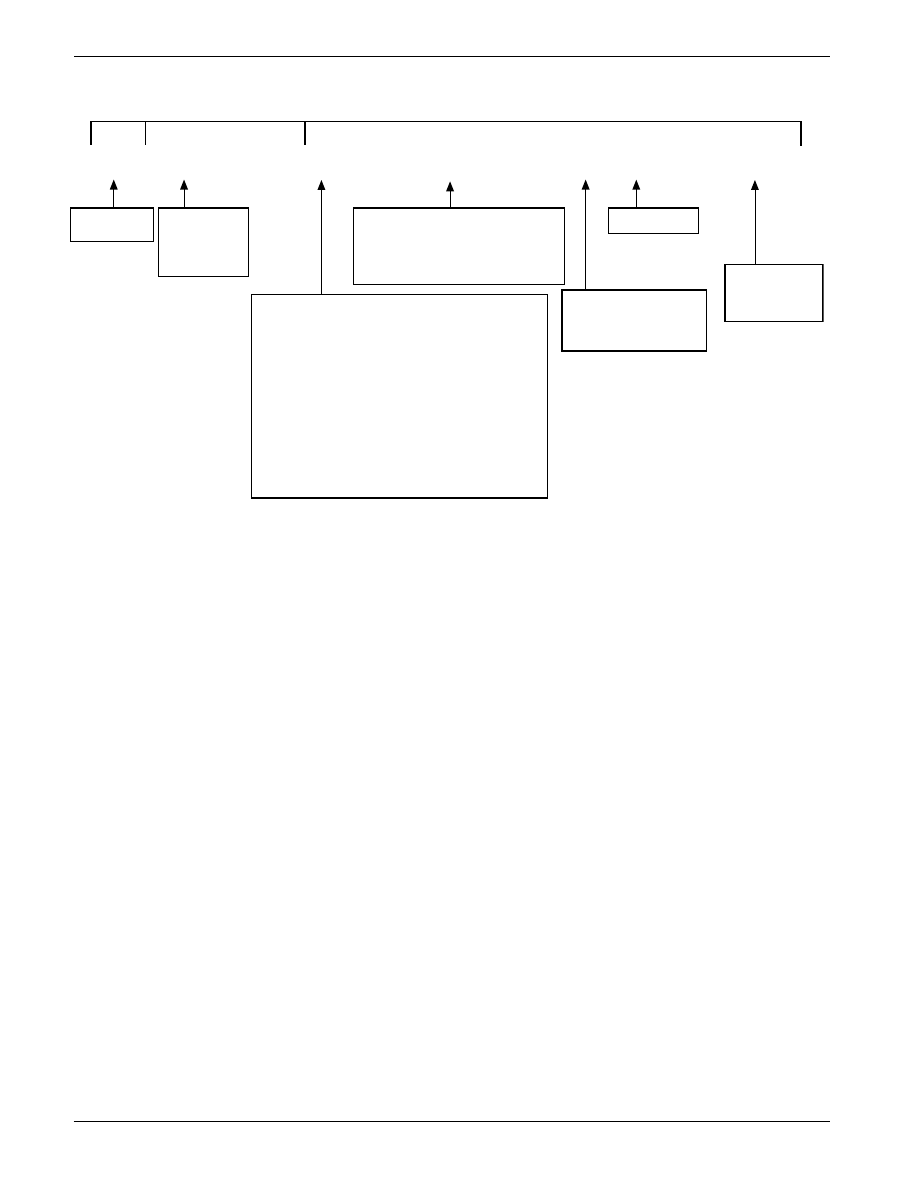

Erase

Upon receiving an ERASE command and address, the

CS (Chip Select) pin must be deasserted for a minimum

of t

CSMIN

. The falling edge of CS will start the self clocking

clear cycle of the selected memory location. The clocking

of the SK pin is not necessary after the device has

entered the self clocking mode. The ready/busy status of

the CAT93C56/57 can be determined by selecting the

device and polling the DO pin. Once cleared, the content

of a cleared location returns to a logical †ś1†ť state.

Erase/Write Enable and Disable

The CAT93C56/57 powers up in the write disable state.

Any writing after power-up or after an EWDS (write

disable) instruction must first be preceded by the EWEN

(write enable) instruction. Once the write instruction is

enabled, it will remain enabled until power to the device

is removed, or the EWDS instruction is sent. The EWDS

instruction can be used to disable all CAT93C56/57

write and clear instructions, and will prevent any

accidental writing or clearing of the device. Data can be

read normally from the device regardless of the write

enable/disable status.

Erase All

Upon receiving an ERAL command, the CS (Chip Select)

pin must be deselected for a minimum of t

CSMIN

. The

falling edge of CS will start the self clocking clear cycle

of all memory locations in the device. The clocking of the

SK pin is not necessary after the device has entered the

self clocking mode. The ready/busy status of the

CAT93C56/57 can be determined by selecting the device

and polling the DO pin. Once cleared, the contents of all

memory bits return to a logical †ś1†ť state.

Write All

Upon receiving a WRAL command and data, the CS

(Chip Select) pin must be deselected for a minimum of

t

CSMIN

. The falling edge of CS will start the self clocking

data write to all memory locations in the device. The

clocking of the SK pin is not necessary after the device

has entered the self clocking mode. The ready/busy

status of the CAT93C56/57 can be determined by

selecting the device and polling the DO pin. It is not

necessary for all memory locations to be cleared before

the WRAL command is executed.

Figure 4. Erase Instruction Timing

SK

CS

DI

DO

STANDBY

HIGH-Z

HIGH-Z

1

AN

AN-1

BUSY

READY

STATUS VERIFY

tSV

tHZ

tEW

tCS

1

1

A0

7

CAT93C56/57

Doc. No. 1088, Rev. M

Figure 7. WRAL Instruction Timing

Figure 5. EWEN/EWDS Instruction Timing

Figure 6. ERAL Instruction Timing

SK

CS

DI

STANDBY

1

0

0

*

* ENABLE=11

DISABLE=00

SK

CS

DI

DO

STANDBY

tCS

HIGH-Z

HIGH-Z

1

0

1

BUSY

READY

STATUS VERIFY

tSV

tHZ

tEW

0

0

STATUS VERIFY

SK

CS

DI

DO

STANDBY

HIGH-Z

1

0

1

BUSY

READY

tSV

tHZ

tEW

tCSMIN

DN

D0

0

0

8

CAT93C56/57

Doc. No. 1088, Rev. M

ORDERING INFORMATION

Notes:

(1) The device used in the above example is a 93C56SI-1.8TE13 (SOIC, Industrial Temperature, 1.8 Volt to 6 Volt Operating Voltage,

Tape & Reel)

(2) Product die revision letter is marked on top of the package as a suffix to the production date code (e.g., AYWWE.) For additional

information, please contact your Catalyst sales office.

Package

P = PDIP

S = SOIC (JEDEC)

J = SOIC (JEDEC)

K = SOIC (EIAJ)

U = TSSOP

RD4 = TDFN (3x3mm)

ZD4 = TDFN (3x3mm, Lead free, Halogen free)

L = PDIP (Lead free, Halogen free)

V = SOIC, JEDEC (Lead free, Halogen free)

W = SOIC, JEDEC (Lead free, Halogen free)

X = SOIC, EIAJ (Lead free, Halogen free)

Y = TSSOP (Lead free, Halogen free)

Prefix

Device #

Suffix

93C56

S

I

TE13

Product

Number

93C56: 2K

93C57: 2K

Tape & Reel

-1.8

CAT

Temperature Range

Blank = Commercial (0

°C - 70 °C)

I = Industrial (-40

°C - 85 °C)

A = Automotive (-40

°C - 105 °C)

Operating Voltage

Blank (V

cc

=2.5 to 6.0V)

1.8 (V

cc

=1.8 to 6.0V)

Optional

Company ID

E = Extended (-40

°C to + 125 °C)

Die Revision

93C56: E

93C57: E

Rev E

(2)

Copyrights, Trademarks and Patents

Trademarks and registered trademarks of Catalyst Semiconductor include each of the following:

DPP ™

AE

2

™

Catalyst Semiconductor has been issued U.S. and foreign patents and has patent applications pending that protect its products. For a complete list of patents

issued to Catalyst Semiconductor contact the Company’s corporate office at 408.542.1000.

CATALYST SEMICONDUCTOR MAKES NO WARRANTY, REPRESENTATION OR GUARANTEE, EXPRESS OR IMPLIED, REGARDING THE SUITABILITY OF ITS

PRODUCTS FOR ANY PARTICULAR PURPOSE, NOR THAT THE USE OF ITS PRODUCTS WILL NOT INFRINGE ITS INTELLECTUAL PROPERTY RIGHTS OR THE

RIGHTS OF THIRD PARTIES WITH RESPECT TO ANY PARTICULAR USE OR APPLICATION AND SPECIFICALLY DISCLAIMS ANY AND ALL LIABILITY ARISING

OUT OF ANY SUCH USE OR APPLICATION, INCLUDING BUT NOT LIMITED TO, CONSEQUENTIAL OR INCIDENTAL DAMAGES.

Catalyst Semiconductor products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or

other applications intended to support or sustain life, or for any other application in which the failure of the Catalyst Semiconductor product could create a

situation where personal injury or death may occur.

Catalyst Semiconductor reserves the right to make changes to or discontinue any product or service described herein without notice. Products with data sheets

labeled "Advance Information" or "Preliminary" and other products described herein may not be in production or offered for sale.

Catalyst Semiconductor advises customers to obtain the current version of the relevant product information before placing orders. Circuit diagrams illustrate

typical semiconductor applications and may not be complete.

Catalyst Semiconductor, Inc.

Corporate Headquarters

1250 Borregas Avenue

Sunnyvale, CA 94089

Phone: 408.542.1000

Fax: 408.542.1200

www.catalyst-semiconductor.com

Publication #:

1088

Revison:

M

Issue date:

10/7/04

REVISION HISTORY

e

t

a

D

n

o

i

s

i

v

e

R

s

t

n

e

m

m

o

C

4

0

/

4

1

/

5

0

L

s

t

r

a

P

.

6

8

/

6

6

/

7

5

/

6

5

/

6

4

C

3

9

T

A

C

m

o

r

F

d

e

t

a

e

r

C

t

e

e

h

S

a

t

a

D

w

e

N

d

n

a

6

7

C

3

9

T

A

C

,

6

6

C

3

9

T

A

C

,

7

5

C

3

9

T

A

C

,

6

5

C

3

9

T

A

C

,

6

5

C

3

9

T

A

C

s

t

e

e

h

s

a

t

a

d

e

l

g

n

i

s

o

t

n

i

d

e

t

a

t

r

a

p

e

s

n

e

e

b

e

v

a

h

6

8

C

3

9

T

A

C

4

0

/

7

/

0

1

M

t

e

S

n

o

i

t

c

u

r

t

s

n

I

d

e

t

a

d

p

U