| Secciones |

|---|

| Foros Electrónica |

|

|

| Boletines de correo |

|

1

TM

File Number 2864.4

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

|

Intersil and Design is a trademark of Intersil Americas Inc.

Copyright ę Intersil Americas Inc. 2001, All Rights Reserved

ICL8038

Precision Waveform Generator/Voltage

Controlled Oscillator

The ICL8038 waveform generator is a monolithic integrated

circuit capable of producing high accuracy sine, square,

triangular, sawtooth and pulse waveforms with a minimum of

external components. The frequency (or repetition rate) can

be selected externally from 0.001Hz to more than 300kHz

using either resistors or capacitors, and frequency

modulation and sweeping can be accomplished with an

external voltage. The ICL8038 is fabricated with advanced

monolithic technology, using Schottky barrier diodes and

thin film resistors, and the output is stable over a wide range

of temperature and supply variations. These devices may be

interfaced with phase locked loop circuitry to reduce

temperature drift to less than 250ppm/

o

C.

Features

Ľ Low Frequency Drift with Temperature . . . . . 250ppm/

o

C

Ľ Low Distortion . . . . . . . . . . . . . . . 1% (Sine Wave Output)

Ľ High Linearity . . . . . . . . . . .0.1% (Triangle Wave Output)

Ľ Wide Frequency Range . . . . . . . . . . . .0.001Hz to 300kHz

Ľ Variable Duty Cycle . . . . . . . . . . . . . . . . . . . . . 2% to 98%

Ľ High Level Outputs. . . . . . . . . . . . . . . . . . . . . . TTL to 28V

Ľ Simultaneous Sine, Square, and Triangle Wave

Outputs

Ľ Easy to Use - Just a Handful of External Components

Required

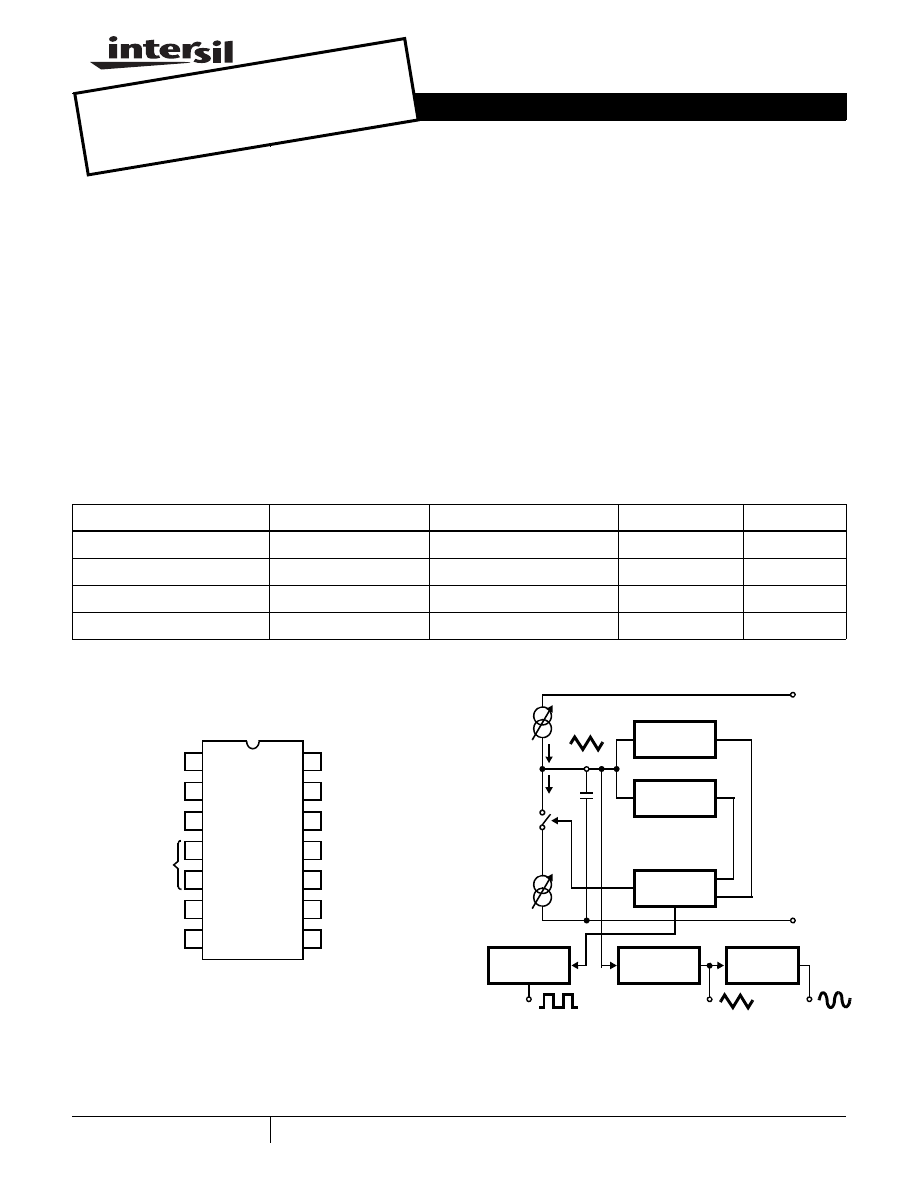

Pinout

ICL8038

(PDIP, CERDIP)

TOP VIEW

Functional Diagram

Ordering Information

PART NUMBER

STABILITY

TEMP. RANGE (

o

C)

PACKAGE

PKG. NO.

ICL8038CCPD 250ppm/

o

C (Typ)

0 to 70

14 Ld PDIP

E14.3

ICL8038CCJD 250ppm/

o

C (Typ)

0 to 70

14 Ld CERDIP

F14.3

ICL8038BCJD 180ppm/

o

C (Typ)

0 to 70

14 Ld CERDIP

F14.3

ICL8038ACJD 120ppm/

o

C (Typ)

0 to 70

14 Ld CERDIP

F14.3

SINE

TRIANGLE

DUTY CYCLE

V+

FM BIAS

NC

NC

SINE WAVE

V- OR GND

TIMING

SQUARE

FM SWEEP

1

2

3

4

5

6

7

14

13

12

11

10

9

8

ADJUST

CAPACITOR

WAVE OUT

INPUT

SINE WAVE

ADJUST

WAVE OUT

OUT

FREQUENCY

ADJUST

COMPARATOR

#1

COMPARATOR

#2

FLIP-FLOP

SINE

CONVERTER

BUFFER

BUFFER

9

2

11

I

10

6

V+

V- OR GND

CURRENT

SOURCE

#1

CURRENT

SOURCE

#2

2I

C

3

Data Sheet

April 2001

[ /Title

(ICL80

38)

/Sub-

ject

(Preci-

sion

Wave-

form

Gener-

ator/Vo

ltage

Con-

trolled

Oscil-

lator)

/Autho

r ()

/Key-

words

(Inter-

sil

Corpo-

ration,

semi-

con-

ductor,

wave-

form

genera-

tor,

volt-

age

con-

trolled

oscilla-

tor,

preci-

sion,

OBSOL

ETE PR

ODUCT

NO REC

OMMEN

DED RE

PLACEM

ENT

contact

our Tec

hnical S

upport C

enter at

1-888-IN

TERSIL

or www

.intersil

.com/ts

c

2

Absolute Maximum Ratings

Thermal Information

Supply Voltage (V- to V+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36V

Input Voltage (Any Pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . V- to V+

Input Current (Pins 4 and 5). . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA

Output Sink Current (Pins 3 and 9) . . . . . . . . . . . . . . . . . . . . . 25mA

Operating Conditions

Temperature Range

ICL8038AC, ICL8038BC, ICL8038CC . . . . . . . . . . . . 0

o

C to 70

o

C

Thermal Resistance (Typical, Note 1)

Θ

JA

(

o

C/W)

Θ

JC

(

o

C/W)

CERDIP Package. . . . . . . . . . . . . . . . .

75

20

PDIP Package . . . . . . . . . . . . . . . . . . .

115

N/A

Maximum Junction Temperature (Ceramic Package) . . . . . . . .175

o

C

Maximum Junction Temperature (Plastic Package) . . . . . . . .150

o

C

Maximum Storage Temperature Range . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

o

C

Die Characteristics

Back Side Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V-

CAUTION: Stresses above those listed in ćťAbsolute Maximum RatingsćŁ may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

Θ

JA

is measured with the component mounted on an evaluation PC board in free air.

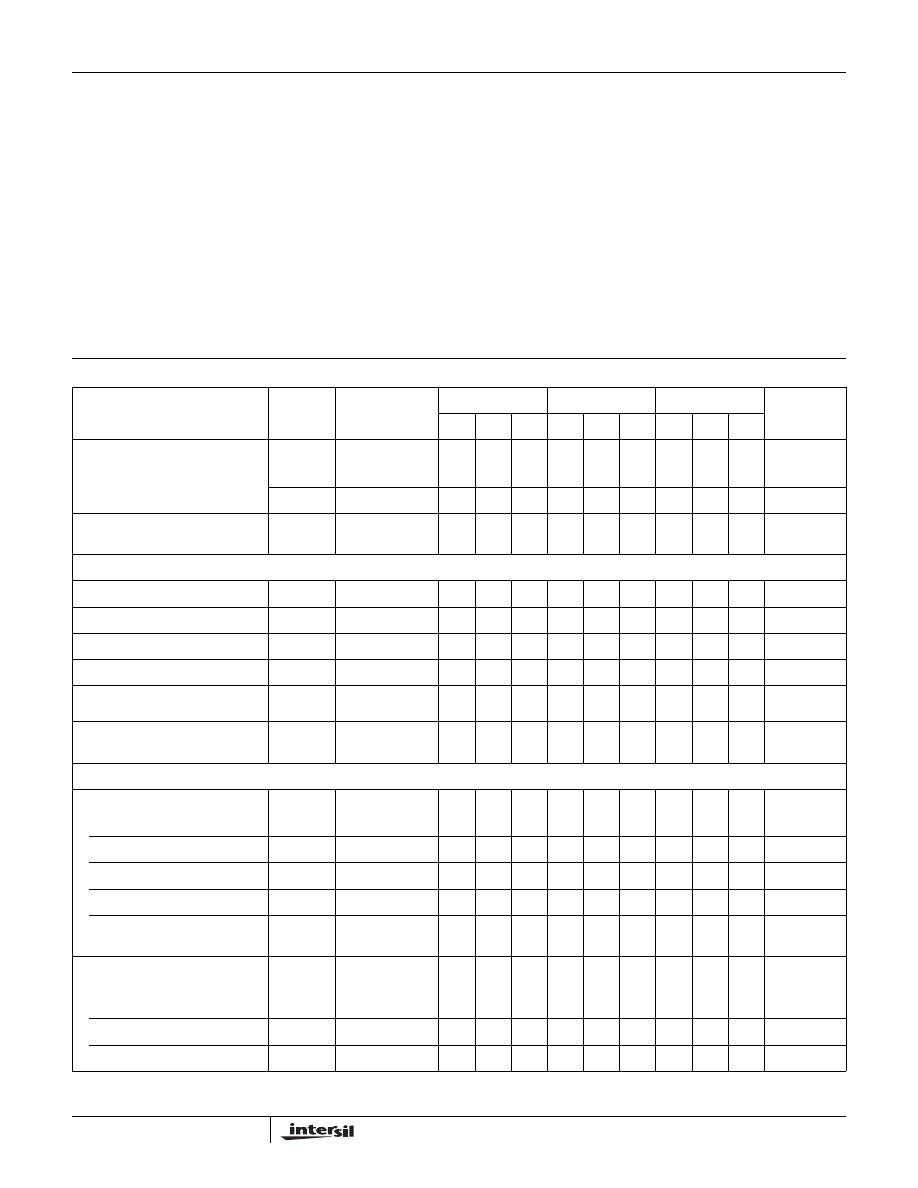

Electrical Specifications

V

SUPPLY

=

▒10V or +20V, T

A

= 25

o

C, R

L

= 10k

Ω, Test Circuit Unless Otherwise Specified

PARAMETER

SYMBOL

TEST

CONDITIONS

ICL8038CC

ICL8038BC

ICL8038AC

UNITS

MIN TYP MAX MIN TYP MAX MIN TYP MAX

Supply Voltage Operating Range

V

SUPPLY

V+

Single Suppl

y

+10

-

+30

+10

-

+30

+10

-

+30

V

V+, V-

Dual Supplies

▒5

-

▒15

▒5

-

▒15

▒5

-

▒15

V

Supply Current

I

SUPPLY

V

SUPPLY

=

▒10V

(Note 2)

12

20

-

12

20

-

12

20

mA

FREQUENCY CHARACTERISTICS (All Waveforms)

Max. Frequency of Oscillation

f

MAX

100

-

-

100

-

-

100

-

-

kHz

Sweep Frequency of FM Input

f

SWEEP

-

10

-

-

10

-

-

10

-

kHz

Sweep FM Range

(Note 3)

-

35:1

-

-

35:1

-

-

35:1

-

FM Linearity

10:1 Ratio

-

0.5

-

-

0.2

-

-

0.2

-

%

Frequency Drift with

Temperature (Note 5)

Δf/ΔT

0

o

C to 70

o

C

-

250

-

-

180

-

-

120

ppm/

o

C

Frequency Drift with Supply Voltage

Δf/ΔV

Over Supply

Voltage Range

-

0.05

-

-

0.05

-

0.05

-

%/V

OUTPUT CHARACTERISTICS

Square Wave

Leakage Current

I

OLK

V

9

= 30V

-

-

1

-

-

1

-

-

1

μA

Saturation Voltage

V

SAT

I

SINK

= 2mA

-

0.2

0.5

-

0.2

0.4

-

0.2

0.4

V

Rise Time

t

R

R

L

= 4.7k

Ω

-

180

-

-

180

-

-

180

-

ns

Fall Time

t

F

R

L

= 4.7k

Ω

-

40

-

-

40

-

-

40

-

ns

Typical Duty Cycle Adjust

(Note 6)

ΔD

2

98

2

-

98

2

-

98

%

Triangle/Sawtooth/Ramp

-

Amplitude

V

TRIAN-

GLE

R

TRI

= 100k

Ω

0.30 0.33

-

0.30 0.33

-

0.30 0.33

-

xV

SUPPLY

Linearity

-

0.1

-

-

0.05

-

-

0.05

-

%

Output Impedance

Z

OUT

I

OUT

= 5mA

-

200

-

-

200

-

-

200

-

Ω

ICL8038

3

Sine Wave

Amplitude

V

SINE

R

SINE

= 100k

Ω

0.2

0.22

-

0.2

0.22

-

0.2

0.22

-

xV

SUPPLY

THD

THD

R

S

= 1M

Ω

(Note 4)

-

2.0

5

-

1.5

3

-

1.0

1.5

%

THD Adjusted

THD

Use Figure 4

-

1.5

-

-

1.0

-

-

0.8

-

%

NOTES:

2. R

A

and R

B

currents not included.

3. V

SUPPLY

= 20V; R

A

and R

B

= 10k

Ω, f Ľëů 10kHz nominal; can be extended 1000 to 1. See Figures 5A and 5B.

4. 82k

Ω connected between pins 11 and 12, Triangle Duty Cycle set at 50%. (Use R

A

and R

B

.)

5. Figure 1, pins 7 and 8 connected, V

SUPPLY

=

▒10V. See Typical Curves for T.C. vs V

SUPPLY

.

6. Not tested, typical value for design purposes only.

Electrical Specifications

V

SUPPLY

=

▒10V or +20V, T

A

= 25

o

C, R

L

= 10k

Ω, Test Circuit Unless Otherwise Specified (Continued)

PARAMETER

SYMBOL

TEST

CONDITIONS

ICL8038CC

ICL8038BC

ICL8038AC

UNITS

MIN TYP MAX MIN TYP MAX MIN TYP MAX

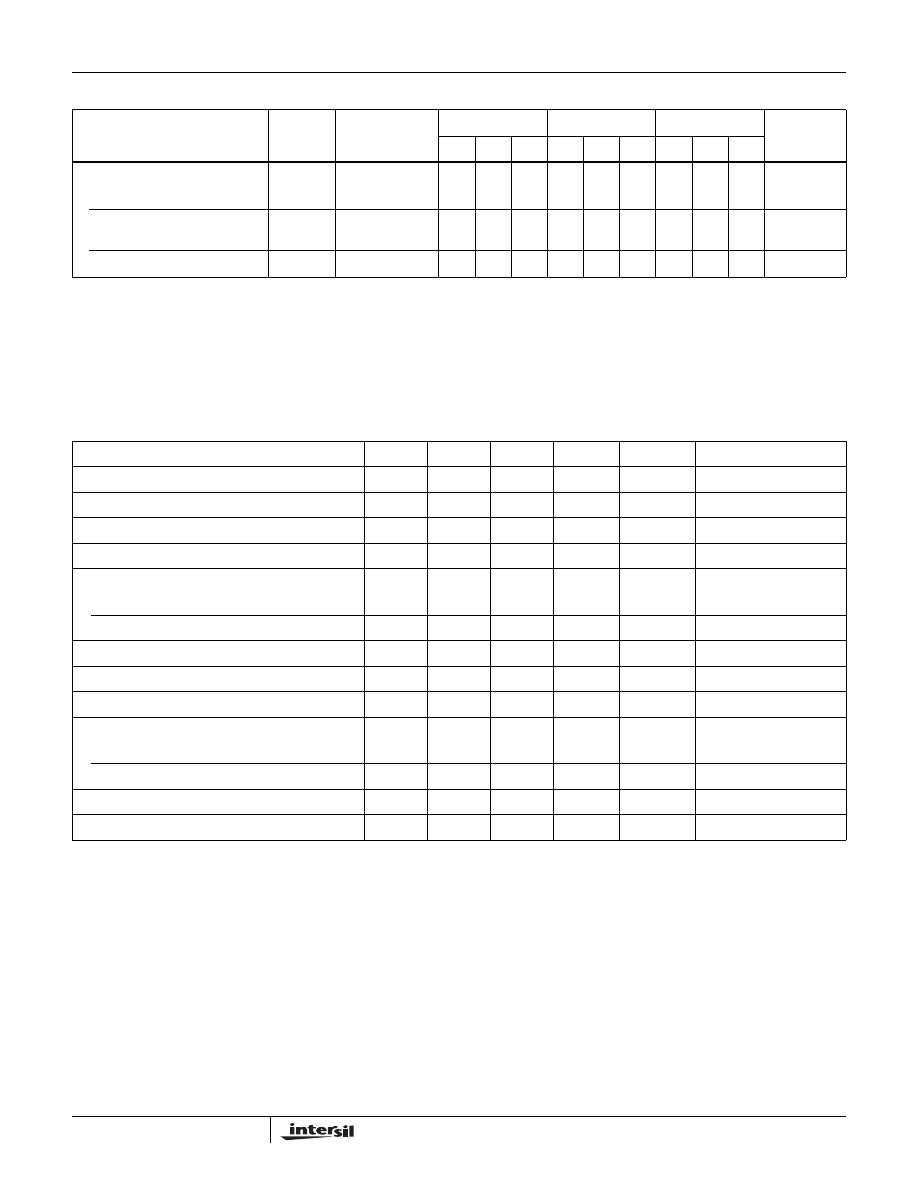

Test Conditions

PARAMETER

R

A

R

B

R

L

C

SW

1

MEASURE

Supply Current

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Current Into Pin 6

Sweep FM Range (Note 7)

10k

Ω

10k

Ω

10k

Ω

3.3nF

Open

Frequency at Pin 9

Frequency Drift with Temperature

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Frequency at Pin 3

Frequency Drift with Supply Voltage (Note 8)

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Frequency at Pin 9

Output Amplitude (Note 10)

Sine

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Pk-Pk Output at Pin 2

Triangle

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Pk-Pk Output at Pin 3

Leakage Current (Off) (Note 9)

10k

Ω

10k

Ω

3.3nF

Closed

Current into Pin 9

Saturation Voltage (On) (Note 9)

10k

Ω

10k

Ω

3.3nF

Closed

Output (Low) at Pin 9

Rise and Fall Times (Note 11)

10k

Ω

10k

Ω

4.7k

Ω

3.3nF

Closed

Waveform at Pin 9

Duty Cycle Adjust (Note 11)

Max

50k

Ω

~1.6k

Ω

10k

Ω

3.3nF

Closed

Waveform at Pin 9

Min

~25k

Ω

50k

Ω

10k

Ω

3.3nF

Closed

Waveform at Pin 9

Triangle Waveform Linearity

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Waveform at Pin 3

Total Harmonic Distortion

10k

Ω

10k

Ω

10k

Ω

3.3nF

Closed

Waveform at Pin 2

NOTES:

7. The hi and lo frequencies can be obtained by connecting pin 8 to pin 7 (f

HI

) and then connecting pin 8 to pin 6 (f

LO

). Otherwise apply Sweep

Voltage at pin 8 (

2

/

3

V

SUPPLY

+2V)

≤ V

SWEEP

≤ V

SUPPLY

where V

SUPPLY

is the total supply voltage. In Figure 5B, pin 8 should vary between

5.3V and 10V with respect to ground.

8. 10V

≤ V+ ≤ 30V, or ▒5V ≤ V

SUPPLY

≤ ▒15V.

9. Oscillation can be halted by forcing pin 10 to +5V or -5V.

10. Output Amplitude is tested under static conditions by forcing pin 10 to 5V then to -5V.

11. Not tested; for design purposes only.

ICL8038

4

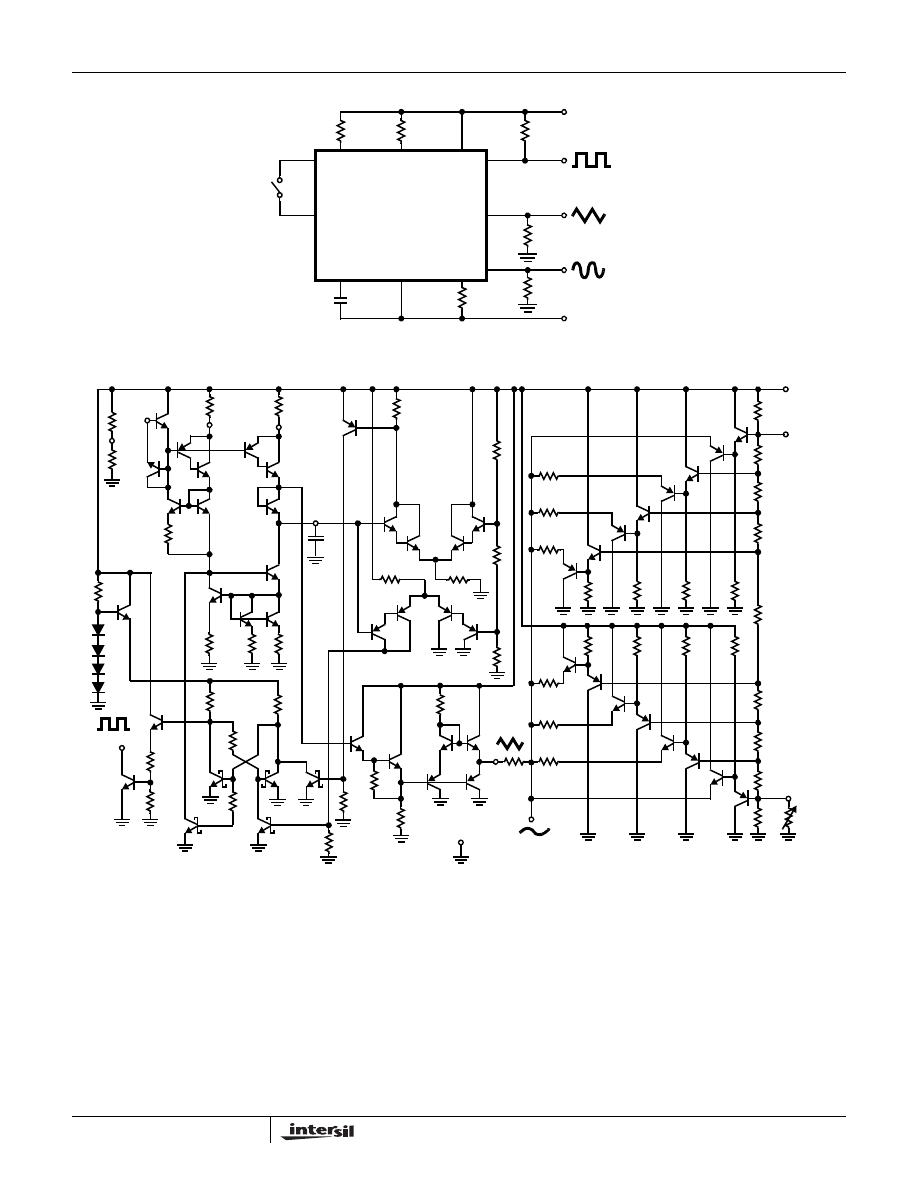

Test Circuit

Application Information

(See Functional Diagram)

An external capacitor C is charged and discharged by two

current sources. Current source #2 is switched on and off by a

flip-flop, while current source #1 is on continuously. Assuming

that the flip-flop is in a state such that current source #2 is off,

and the capacitor is charged with a current I, the voltage

across the capacitor rises linearly with time. When this voltage

reaches the level of comparator #1 (set at 2/3 of the supply

voltage), the flip-flop is triggered, changes states, and

releases current source #2. This current source normally

carries a current 2I, thus the capacitor is discharged with a

net-current I and the voltage across it drops linearly with time.

When it has reached the level of comparator #2 (set at 1/3 of

the supply voltage), the flip-flop is triggered into its original

state and the cycle starts again.

Four waveforms are readily obtainable from this basic

generator circuit. With the current sources set at I and 2I

respectively, the charge and discharge times are equal.

Thus a triangle waveform is created across the capacitor

and the flip-flop produces a square wave. Both waveforms

are fed to buffer stages and are available at pins 3 and 9.

Detailed Schematic

ICL8038

4

5

6 9

2

12

11

10

8

7

SW

1

N.C.

C

3300pF

82K

R

A

10K

R

B

10K

R

L

10K

R

TRI

R

SINE

-10V

3

+10V

FIGURE 1. TEST CIRCUIT

Q

20

Q

21

Q

19

Q

22

Q

31

Q

32

Q

33

Q

34

Q

30

Q

7

Q

6

Q

1

Q

2

Q

4

Q

8

Q

9

Q

5

Q

3

Q

14

Q

11

Q

12

Q

13

Q

24

Q

23

Q

25

Q

26

Q

29

Q

27

Q

28

Q

10

Q

15

Q

18

Q

17

Q

16

Q

35

Q

36

Q

38

Q

40

Q

37

Q

39

R

1

11K

R

2

39K

7

8

5

4

R

EXT

B

R

EXT

A

COMPARATOR

R

41

4K

R

8

5K

R

9

5K

R

10

5K

R

43

27K

R

42

27K

BUFFER AMPLIFIER

R

41

27K

R

17

4.7K

R

18

4.7K

R

14

27K

R

13

620

R

16

1.8K

R

6

100

R

5

100

R

4

100

R

3

30K

R

46

40K

C

EXT

R

7A

10K

R

7B

15K

R

44

1K

3

10

R

11

270

R

12

2.7K

R

15

470

R

24

800

2

R

21

10K

R

20

2.7K

R

19

800

FLIP-FLOP

SINE CONVERTER

Q

49

Q

50

Q

52

Q

51

Q

53

Q

55

Q

54

Q

56

Q

42

Q

41

Q

43

Q

44

Q

45

Q

46

Q

47

Q

48

6

V+

1

12

R

32

5.2K

R

33

200

R

34

375

R

35

330

R

36

1600

R

37

330

R

38

375

R

39

200

R

40

5.6K

R

EXT

C

82K

R

23

2.7K

R

22

10K

R

28

33K

R

30

33K

R

29

33K

R

31

33K

R

25

33K

R

26

33K

R

27

33K

R

45

33K

CURRENT SOURCES

9

11

ICL8038

5

The levels of the current sources can, however, be selected

over a wide range with two external resistors. Therefore, with

the two currents set at values different from I and 2I, an

asymmetrical sawtooth appears at Terminal 3 and pulses

with a duty cycle from less than 1% to greater than 99% are

available at Terminal 9.

The sine wave is created by feeding the triangle wave into a

nonlinear network (sine converter). This network provides a

decreasing shunt impedance as the potential of the triangle

moves toward the two extremes.

Waveform Timing

The symmetry of all waveforms can be adjusted with the

external timing resistors. Two possible ways to accomplish

this are shown in Figure 3. Best results are obtained by

keeping the timing resistors R

A

and R

B

separate (A). R

A

controls the rising portion of the triangle and sine wave and

the 1 state of the square wave.

The magnitude of the triangle waveform is set at

1

/

3

V

SUPPLY

; therefore the rising portion of the triangle is,

The falling portion of the triangle and sine wave and the 0

state of the square wave is:

Thus a 50% duty cycle is achieved when R

A

= R

B

.

If the duty cycle is to be varied over a small range about 50%

only, the connection shown in Figure 3B is slightly more

convenient. A 1k

Ω potentiometer may not allow the duty cycle

to be adjusted through 50% on all devices. If a 50% duty cycle

is required, a 2k

Ω or 5kΩ potentiometer should be used.

With two separate timing resistors, the frequency is given by:

or, if R

A

= R

B

= R

t

1

C V

×

I

--------------

C 1/3 V

SUPPLY

R

A

×

×

×

0.22 V

SUPPLY

×

-------------------------------------------------------------------

R

A

C

×

0.66

------------------

=

=

=

t

2

C

V

×

1

-------------

C

1/3V

SUPPLY

×

2 0.22

(

)

V

SUPPLY

R

B

------------------------

0.22

V

SU PPLY

R

A

------------------------

-

-----------------------------------------------------------------------------------

R

A

R

B

C

0.66 2RA RB

-

(

)

-------------------------------------

=

=

=

f

1

t

1

t

2

+

----------------

1

R

A

C

0.66

------------

1

R

B

2R

A

R

B

-

-------------------------

+

ĽÄŁ

ĽÄá

ĽÄť

ĽÄč

ĽÄŤ

ĽÄ×

------------------------------------------------------

=

=

f

0.33

RC

-----------

(for Figure 3A)

=

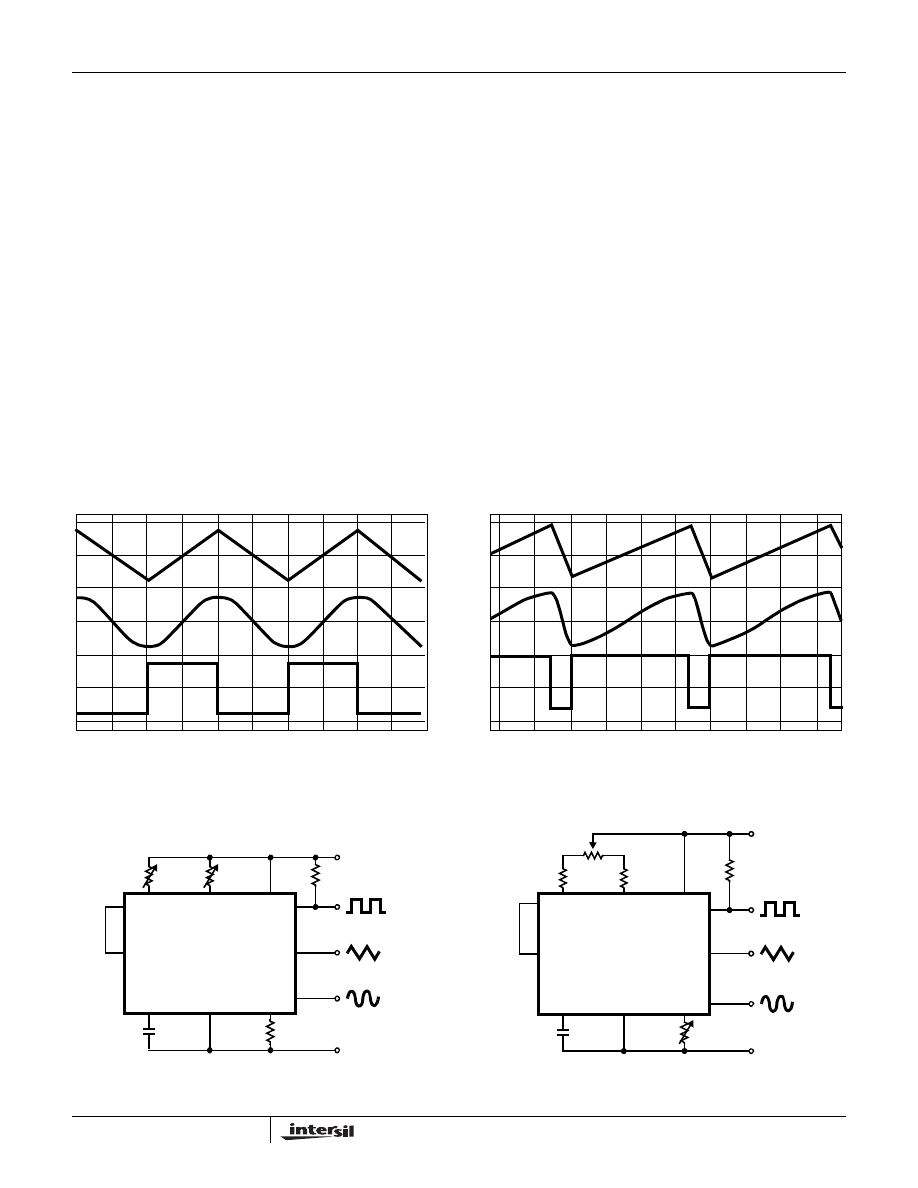

FIGURE 2A. SQUARE WAVE DUTY CYCLE - 50%

FIGURE 2B. SQUARE WAVE DUTY CYCLE - 80%

FIGURE 2. PHASE RELATIONSHIP OF WAVEFORMS

FIGURE 3A.

FIGURE 3B.

FIGURE 3. POSSIBLE CONNECTIONS FOR THE EXTERNAL TIMING RESISTORS

C

82K

ICL8038

4

5

6 9

2

12

11

10

8

7

R

A

R

L

V- OR GND

3

R

B

V+

ICL8038

4

5

6 9

2

12

11

10

8

7

C

100K

R

A

R

L

V- OR GND

3

R

B

V+

1k

Ω

ICL8038

6

Neither time nor frequency are dependent on supply voltage,

even though none of the voltages are regulated inside the

integrated circuit. This is due to the fact that both currents

and thresholds are direct, linear functions of the supply

voltage and thus their effects cancel.

Reducing Distortion

To minimize sine wave distortion the 82k

Ω resistor between

pins 11 and 12 is best made variable. With this arrangement

distortion of less than 1% is achievable. To reduce this even

further, two potentiometers can be connected as shown in

Figure 4; this configuration allows a typical reduction of sine

wave distortion close to 0.5%.

Selecting R

A

, R

B

and C

For any given output frequency, there is a wide range of RC

combinations that will work, however certain constraints are

placed upon the magnitude of the charging current for

optimum performance. At the low end, currents of less than

1

μA are undesirable because circuit leakages will contribute

significant errors at high temperatures. At higher currents

(I > 5mA), transistor betas and saturation voltages will

contribute increasingly larger errors. Optimum performance

will, therefore, be obtained with charging currents of 10

μA to

1mA. If pins 7 and 8 are shorted together, the magnitude of

the charging current due to R

A

can be calculated from:

R

1

and R

2

are shown in the Detailed Schematic.

A similar calculation holds for R

B

.

The capacitor value should be chosen at the upper end of its

possible range.

Waveform Out Level Control and Power Supplies

The waveform generator can be operated either from a

single power supply (10V to 30V) or a dual power supply

(

▒5V to ▒15V). With a single power supply the average

levels of the triangle and sine wave are at exactly one-half of

the supply voltage, while the square wave alternates

between V+ and ground. A split power supply has the

advantage that all waveforms move symmetrically about

ground.

The square wave output is not committed. A load resistor

can be connected to a different power supply, as long as the

applied voltage remains within the breakdown capability of

the waveform generator (30V). In this way, the square wave

output can be made TTL compatible (load resistor

connected to +5V) while the waveform generator itself is

powered from a much higher voltage.

Frequency Modulation and Sweeping

The frequency of the waveform generator is a direct function

of the DC voltage at Terminal 8 (measured from V+). By

altering this voltage, frequency modulation is performed. For

small deviations (e.g.

▒10%) the modulating signal can be

applied directly to pin 8, merely providing DC decoupling

with a capacitor as shown in Figure 5A. An external resistor

between pins 7 and 8 is not necessary, but it can be used to

increase input impedance from about 8k

Ω (pins 7 and 8

connected together), to about (R + 8k

Ω).

For larger FM deviations or for frequency sweeping, the

modulating signal is applied between the positive supply

voltage and pin 8 (Figure 5B). In this way the entire bias for

the current sources is created by the modulating signal, and

a very large (e.g. 1000:1) sweep range is created

(f = Minimum at V

SWEEP

= 0, i.e., Pin 8 = V+). Care must be

taken, however, to regulate the supply voltage; in this

configuration the charge current is no longer a function of the

supply voltage (yet the trigger thresholds still are) and thus

the frequency becomes dependent on the supply voltage.

The potential on Pin 8 may be swept down from V+ by (

1

/

3

V

SUPPLY

- 2V).

ICL8038

4

5

6 9

2

12

11

10

8

7

C

100k

Ω

R

A

R

L

V- OR GND

3

R

B

V+

1k

Ω

1

10k

Ω

100k

Ω

10k

Ω

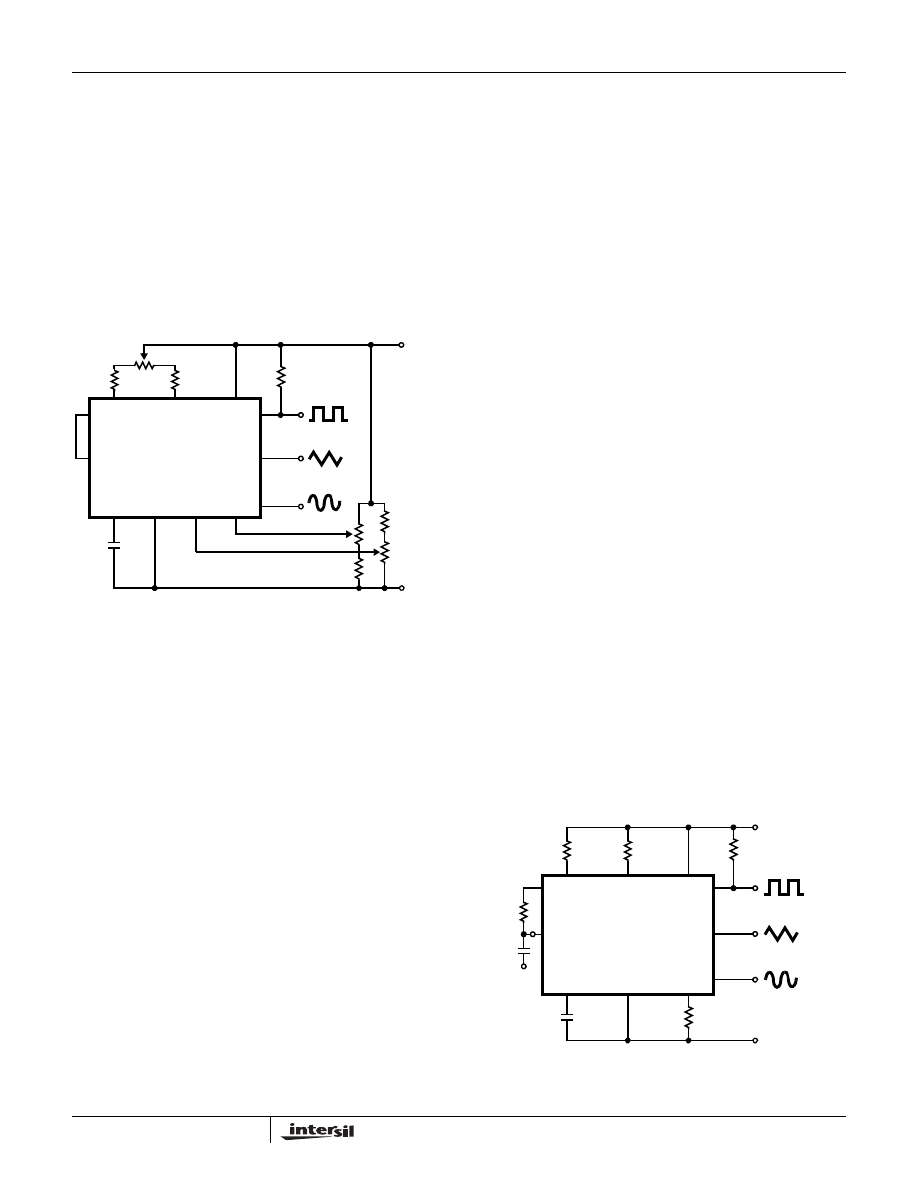

FIGURE 4. CONNECTION TO ACHIEVE MINIMUM SINE

WAVE DISTORTION

I

R

1

V+

V-

-

(

)

×

R

1

R

2

+

(

)

----------------------------------------

1

R

A

--------

×

0.22 V+ V-

-

(

)

R

A

------------------------------------

=

=

C

81K

ICL8038

4

5

6 9

2

12

11

10

8

7

R

A

R

L

V- OR GND

3

R

B

V+

R

FM

FIGURE 5A. CONNECTIONS FOR FREQUENCY MODULATION

ICL8038

7

Typical Applications

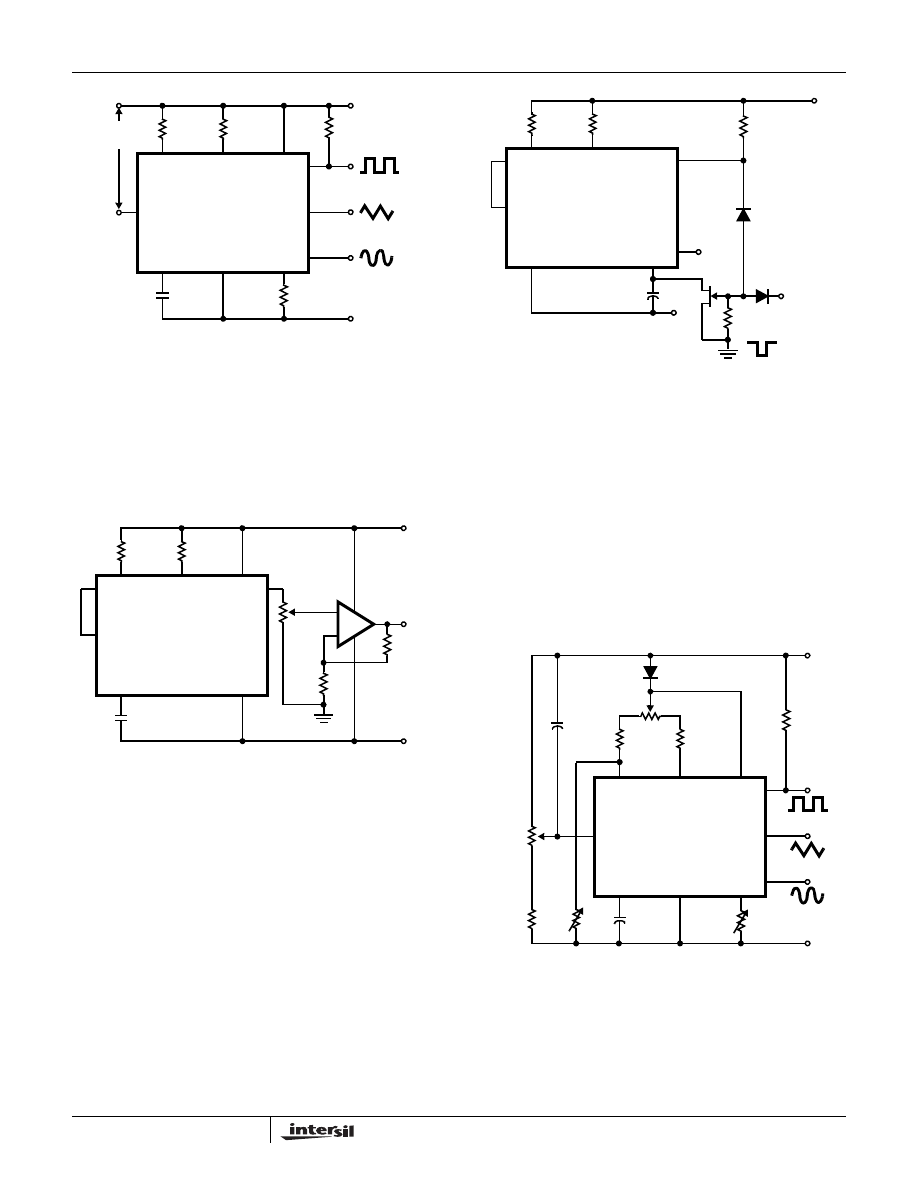

The sine wave output has a relatively high output impedance

(1k

Ω Typ). The circuit of Figure 6 provides buffering, gain

and amplitude adjustment. A simple op amp follower could

also be used.

With a dual supply voltage the external capacitor on Pin 10 can

be shorted to ground to halt the ICL8038 oscillation. Figure 7

shows a FET switch, diode ANDed with an input strobe signal

to allow the output to always start on the same slope.

To obtain a 1000:1 Sweep Range on the ICL8038 the

voltage across external resistors R

A

and R

B

must decrease

to nearly zero. This requires that the highest voltage on

control Pin 8 exceed the voltage at the top of R

A

and R

B

by

a few hundred mV. The Circuit of Figure 8 achieves this by

using a diode to lower the effective supply voltage on the

ICL8038. The large resistor on pin 5 helps reduce duty cycle

variations with sweep.

The linearity of input sweep voltage versus output frequency

can be significantly improved by using an op amp as shown

in Figure 10.

C

81K

ICL8038

4

5

6 9

2

12

11

10

8

R

A

R

L

V- OR GND

3

R

B

V+

SWEEP

VOLTAGE

FIGURE 5B. CONNECTIONS FOR FREQUENCY SWEEP

FIGURE 5.

C

ICL8038

4

5

6 2

11

10

8

7

R

A

100K

V-

R

B

V+

AMPLITUDE

20K

+

-

741

4.7K

FIGURE 6. SINE WAVE OUTPUT BUFFER AMPLIFIERS

C

ICL8038

4

5

9

10

11

8

7

R

A

1N914

-15V

R

B

V+

STROBE

2

2N4392

1N914

15K

100K

OFF

ON

+15V (+10V)

-15V (-10V)

FIGURE 7. STROBE TONE BURST GENERATOR

0.0047

μF

DISTORTION

ICL8038

5

4

6 9

2

12

11

10

8

4.7K

-10V

3

+10V

20K

4.7K

1K

DUTY CYCLE

15K

1N457

0.1

μF

100K

Ľëł

15M

10K

FREQ.

FIGURE 8. VARIABLE AUDIO OSCILLATOR, 20Hz TO 20kHzY

ICL8038

8

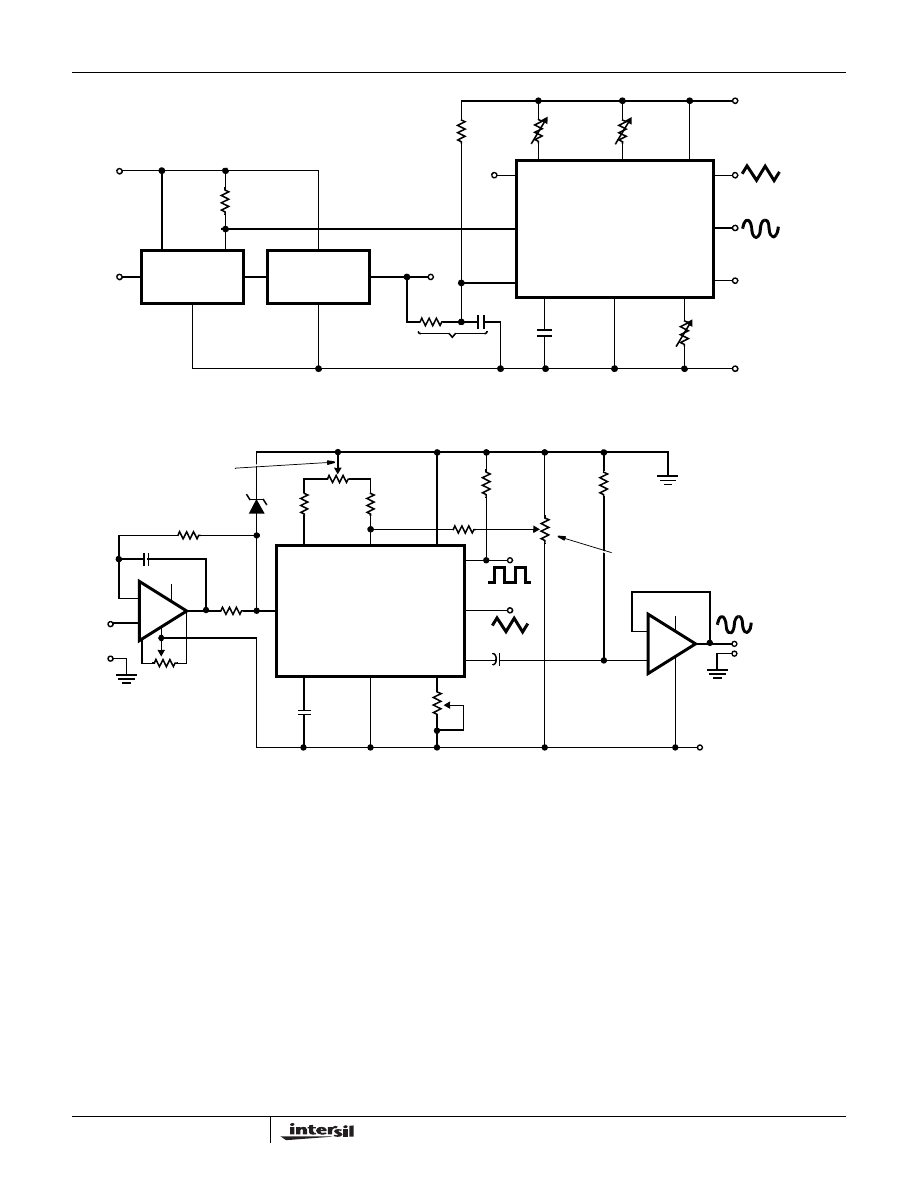

Use in Phase Locked Loops

Its high frequency stability makes the ICL8038 an ideal

building block for a phase locked loop as shown in Figure 9.

In this application the remaining functional blocks, the phase

detector and the amplifier, can be formed by a number of

available ICs (e.g., MC4344, NE562).

In order to match these building blocks to each other, two

steps must be taken. First, two different supply voltages are

used and the square wave output is returned to the supply of

the phase detector. This assures that the VCO input voltage

will not exceed the capabilities of the phase detector. If a

smaller VCO signal is required, a simple resistive voltage

divider is connected between pin 9 of the waveform

generator and the VCO input of the phase detector.

Second, the DC output level of the amplifier must be made

compatible to the DC level required at the FM input of the

waveform generator (pin 8, 0.8V+). The simplest solution here

is to provide a voltage divider to V+ (R

1

, R

2

as shown) if the

amplifier has a lower output level, or to ground if its level is

higher. The divider can be made part of the low-pass filter.

This application not only provides for a free-running

frequency with very low temperature drift, but is also has the

unique feature of producing a large reconstituted sinewave

signal with a frequency identical to that at the input.

For further information, see Intersil Application Note AN013,

ćťEverything You Always Wanted to Know About the ICL8038ćŁ.

SINE WAVE

ICL8038

4

5

6 3

1

12

11

10

8

7

R

1

V-/GND

2

DUTY

V

2

+

CYCLE

FREQUENCY

ADJUST

ADJ.

9

SINE WAVE

TRIANGLE

OUT

SINE WAVE

ADJ.

TIMING

CAP.

FM BIAS

SQUARE

WAVE

OUT

R

2

LOW PASS

FILTER

DEMODULATED

FM

AMPLIFIER

PHASE

DETECTOR

VCO

IN

INPUT

V

1

+

OUT

FIGURE 9. WAVEFORM GENERATOR USED AS STABLE VCO IN A PHASE-LOCKED LOOP

3,900pF

SINE WAVE

ICL8038

4

5

6

9

2

12

11

10

8

4.7k

Ω

3

4.7k

Ω

500

Ω

10k

Ω

1N753A

DISTORTION

FUNCTION GENERATOR

100k

Ω

+

50

μF

15V

1M

Ω

(6.2V)

HIGH FREQUENCY

SYMMETRY

100k

Ω

LOW FREQUENCY

SYMMETRY

100k

Ω

+

-

741

+15V

-15V

SINE WAVE

OUTPUT

+

-

741

+15V

1k

Ω

10k

Ω

OFFSET

-V

IN

P

4

1,000pF

1k

Ω

FIGURE 10. LINEAR VOLTAGE CONTROLLED OSCILLATOR

ICL8038

9

Definition of Terms

Supply Voltage (V

SUPPLY

). The total supply voltage from

V+ to V-.

Supply Current. The supply current required from the

power supply to operate the device, excluding load currents

and the currents through R

A

and R

B

.

Frequency Range. The frequency range at the square wave

output through which circuit operation is guaranteed.

Sweep FM Range. The ratio of maximum frequency to

minimum frequency which can be obtained by applying a

sweep voltage to pin 8. For correct operation, the sweep

voltage should be within the range:

(

2

/

3

V

SUPPLY

+ 2V) < V

SWEEP

< V

SUPPLY

FM Linearity. The percentage deviation from the best fit

straight line on the control voltage versus output frequency

curve.

Output Amplitude. The peak-to-peak signal amplitude

appearing at the outputs.

Saturation Voltage. The output voltage at the collector of

Q

23

when this transistor is turned on. It is measured for a

sink current of 2mA.

Rise and Fall Times. The time required for the square wave

output to change from 10% to 90%, or 90% to 10%, of its

final value.

Triangle Waveform Linearity. The percentage deviation

from the best fit straight line on the rising and falling triangle

waveform.

Total Harmonic Distortion. The total harmonic distortion at

the sine wave output.

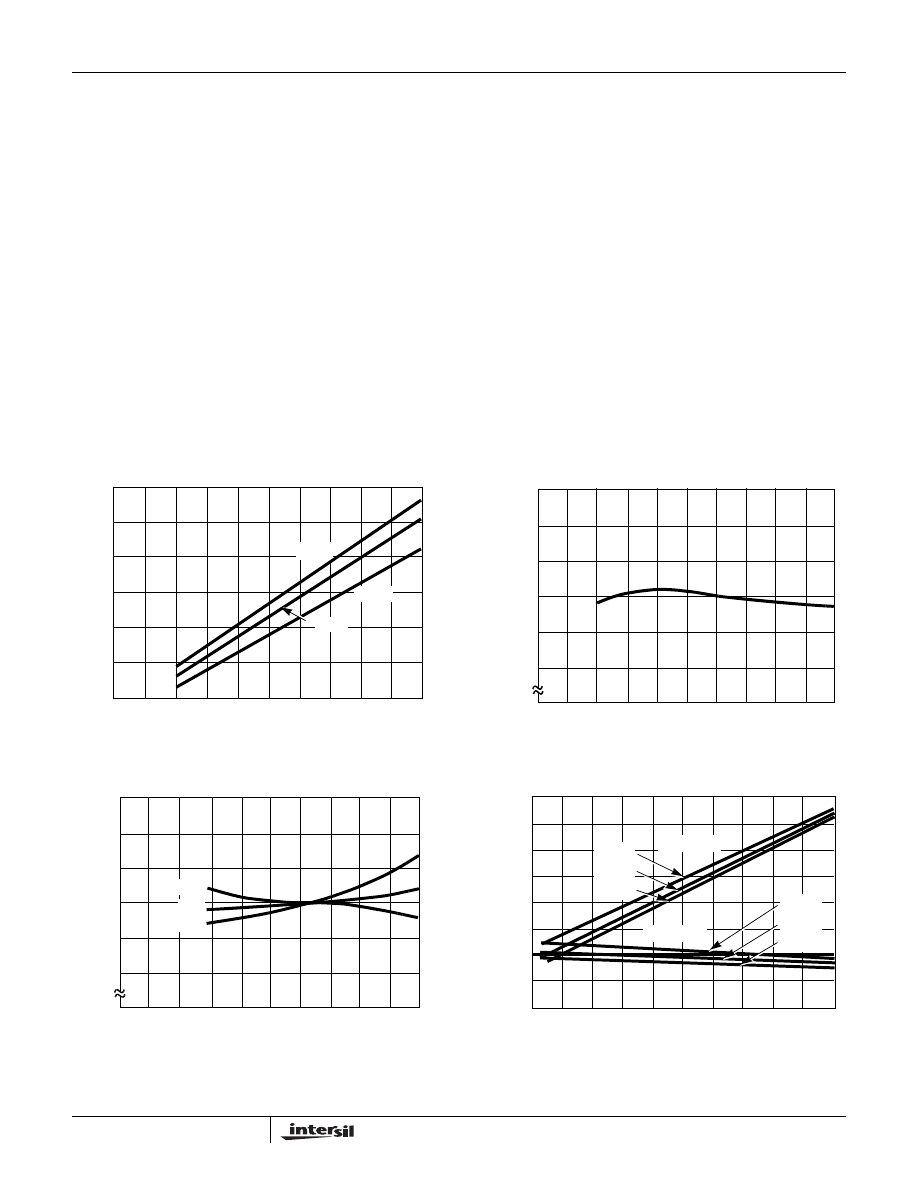

Typical Performance Curves

FIGURE 11. SUPPLY CURRENT vs SUPPLY VOLTAGE

FIGURE 12. FREQUENCY vs SUPPLY VOLTAGE

FIGURE 13. FREQUENCY vs TEMPERATURE

FIGURE 14. SQUARE WAVE OUTPUT RISE/FALL TIME vs

LOAD RESISTANCE

SUPPLY VOLTAGE (V)

SUPPLY

CURRENT (

m

A)

5

10

15

20

25

30

5

10

15

20

25

o

C

125

o

C

-55

o

C

SUPPLY VOLTAGE (V)

NORMALIZE

D

FREQU

E

NCY

5

10

15

20

25

30

0.98

0.99

1.01

1.03

1.00

1.02

TEMPERATURE (

o

C)

NORMA

L

IZED F

R

E

Q

UENCY

-50

-25

0

25

75

125

0.98

0.99

1.01

1.03

1.00

1.02

30V

20V

10V

20V

30V

10V

LOAD RESISTANCE (k

Ω)

10

6

4

2

0

8

0

50

100

150

200

TIME

(ns

)

125

o

C

FALL TIME

RISE TIME

25

o

C

-55

o

C

125

o

C

25

o

C

-55

o

C

ICL8038

10

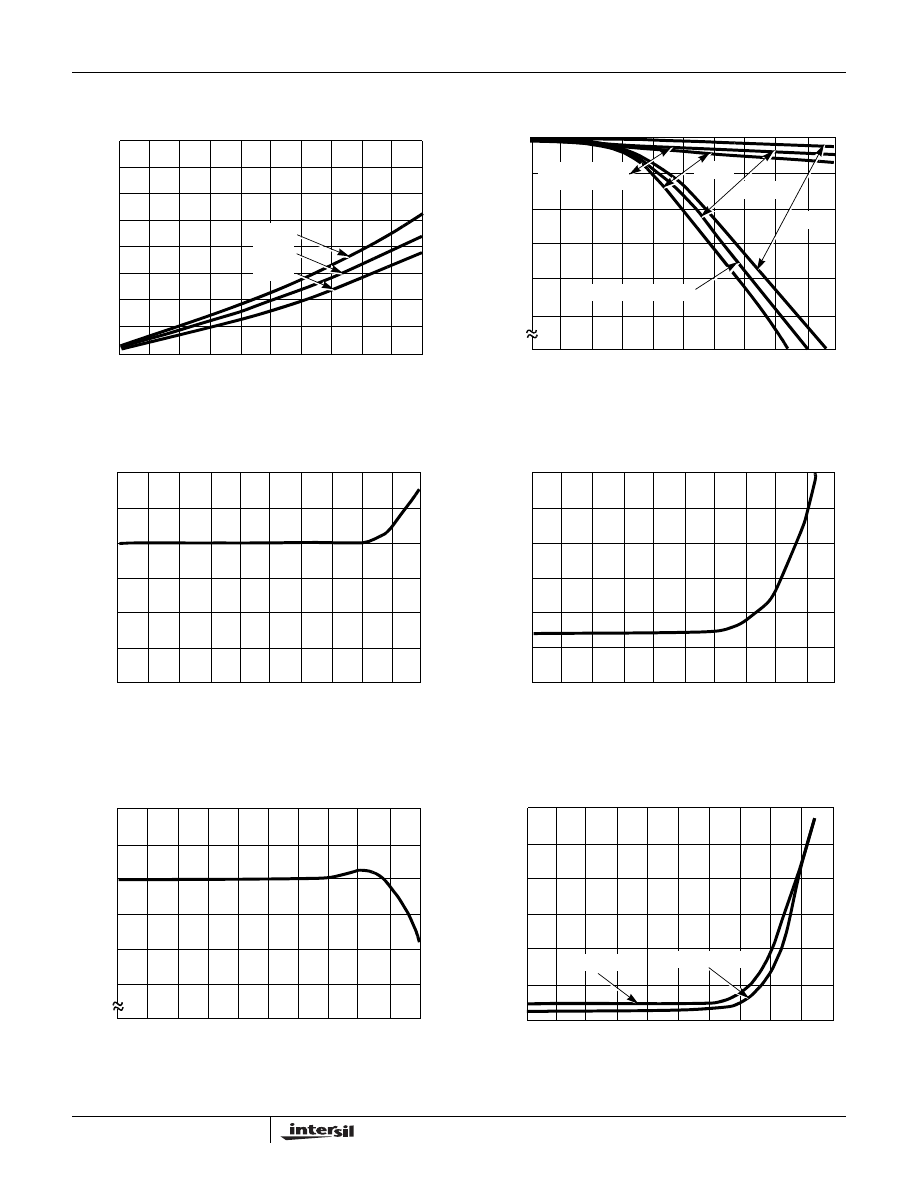

FIGURE 15. SQUARE WAVE SATURATION VOLTAGE vs

LOAD CURRENT

FIGURE 16. TRIANGLE WAVE OUTPUT VOLTAGE vs LOAD

CURRENT

FIGURE 17. TRIANGLE WAVE OUTPUT VOLTAGE vs

FREQUENCY

FIGURE 18. TRIANGLE WAVE LINEARITY vs FREQUENCY

FIGURE 19. SINE WAVE OUTPUT VOLTAGE vs FREQUENCY

FIGURE 20. SINE WAVE DISTORTION vs FREQUENCY

Typical Performance Curves

(Continued)

LOAD CURRENT (mA)

S

A

TURATION V

O

LTAGE

10

6

4

2

0

8

2

1.5

1.0

0.5

0

125

o

C

25

o

C

-55

o

C

LOAD CURRENT (mA)

NORMA

L

IZED PEAK OUTPUT

V

O

LTAGE

16

6

4

2

0

10

20

18

14

12

8

0.8

0.9

1.0

LOAD CURRENT

LOAD CURRENT TO V+

25

o

C

125

o

C

-55

o

C

TO V -

FREQUENCY (Hz)

10K

1K

100

10

1M

100K

0.6

0.7

0.8

0.9

1.0

1.1

1.2

NORMALIZED OUTPUT VOLTAGE

FREQUENCY (Hz)

10K

1K

100

10

1M

100K

0.01

0.1

1.0

10.0

LINEARITY

(%)

FREQUENCY (Hz)

10K

1K

100

10

1M

100K

0.9

1.0

1.1

NORMALIZ

E

D

OUT

P

UT

VOLT

AGE

ADJUSTED

FREQUENCY (Hz)

10K

1K

100

10

1M

100K

2

4

6

DIS

T

ORT

IO

N

(%

)

0

8

10

12

UNADJUSTED

ICL8038

11

ICL8038

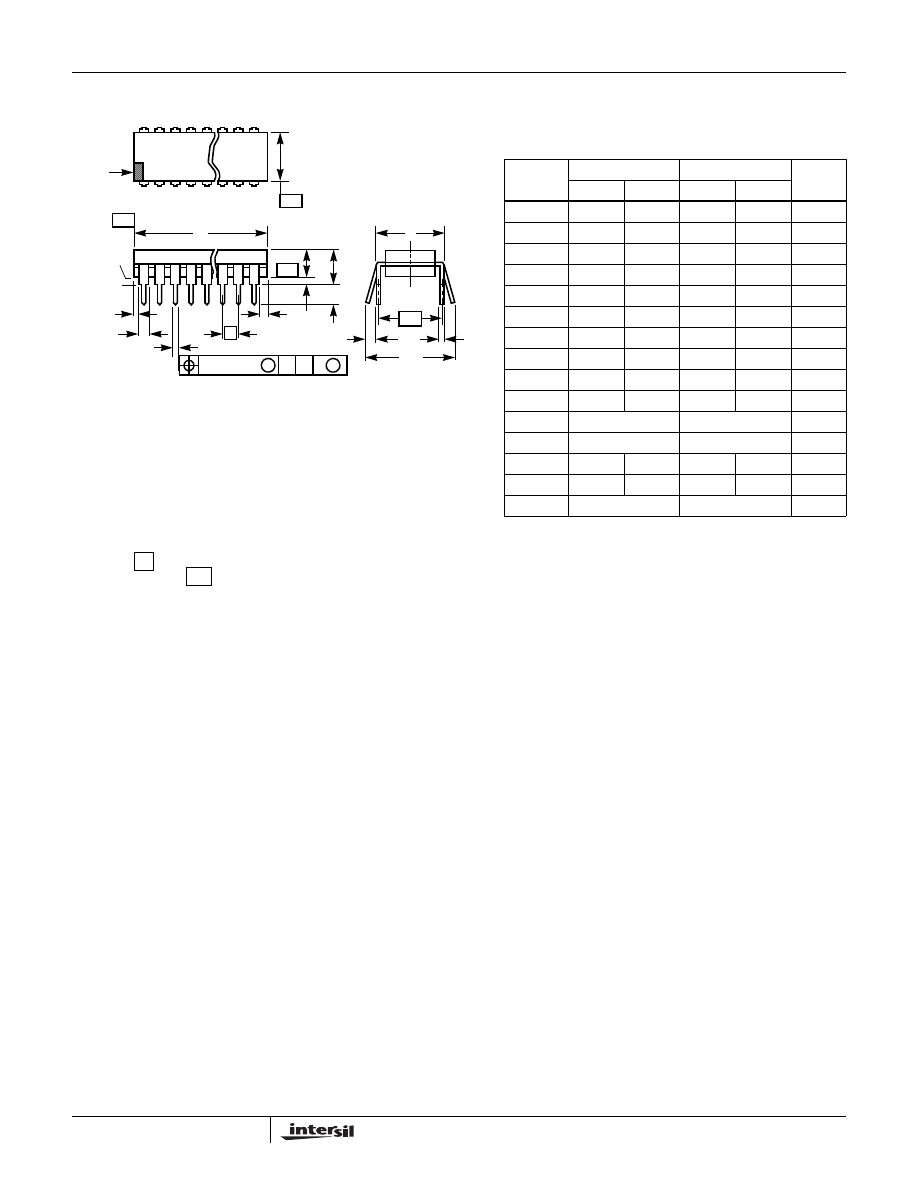

Dual-In-Line Plastic Packages (PDIP)

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English

and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the ćťMO Series Symbol ListćŁ in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and

are measured with the leads constrained to be perpen-

dicular to datum

.

7. e

B

and e

C

are measured at the lead tips with the leads uncon-

strained. e

C

must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 -

1.14mm).

e

A

-C-

CL

E

e

A

C

e

B

e

C

-B-

E1

INDEX

1 2 3

N/2

N

AREA

SEATING

BASE

PLANE

PLANE

-C-

D1

B1

B

e

D

D1

A

A2

L

A1

-A-

0.010 (0.25)

C A

M

B S

E14.3

(JEDEC MS-001-AA ISSUE D)

14 LEAD DUAL-IN-LINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.210

-

5.33

4

A1

0.015

-

0.39

-

4

A2

0.115

0.195

2.93

4.95

-

B

0.014

0.022

0.356

0.558

-

B1

0.045

0.070

1.15

1.77

8

C

0.008

0.014

0.204

0.355

-

D

0.735

0.775

18.66

19.68

5

D1

0.005

-

0.13

-

5

E

0.300

0.325

7.62

8.25

6

E1

0.240

0.280

6.10

7.11

5

e

0.100 BSC

2.54 BSC

-

e

A

0.300 BSC

7.62 BSC

6

e

B

-

0.430

-

10.92

7

L

0.115

0.150

2.93

3.81

4

N

14

14

9

Rev. 0 12/93

12

All Intersil products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporationĺs quality certifications can be viewed at website www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice.

Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and reliable. How-

ever, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result from its use.

No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

2401 Palm Bay Rd., Mail Stop 53-204

Palm Bay, FL 32905

TEL: (321) 724-7000

FAX: (321) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil Ltd.

8F-2, 96, Sec. 1, Chien-kuo North,

Taipei, Taiwan 104

Republic of China

TEL: 886-2-2515-8508

FAX: 886-2-2515-8369

ICL8038

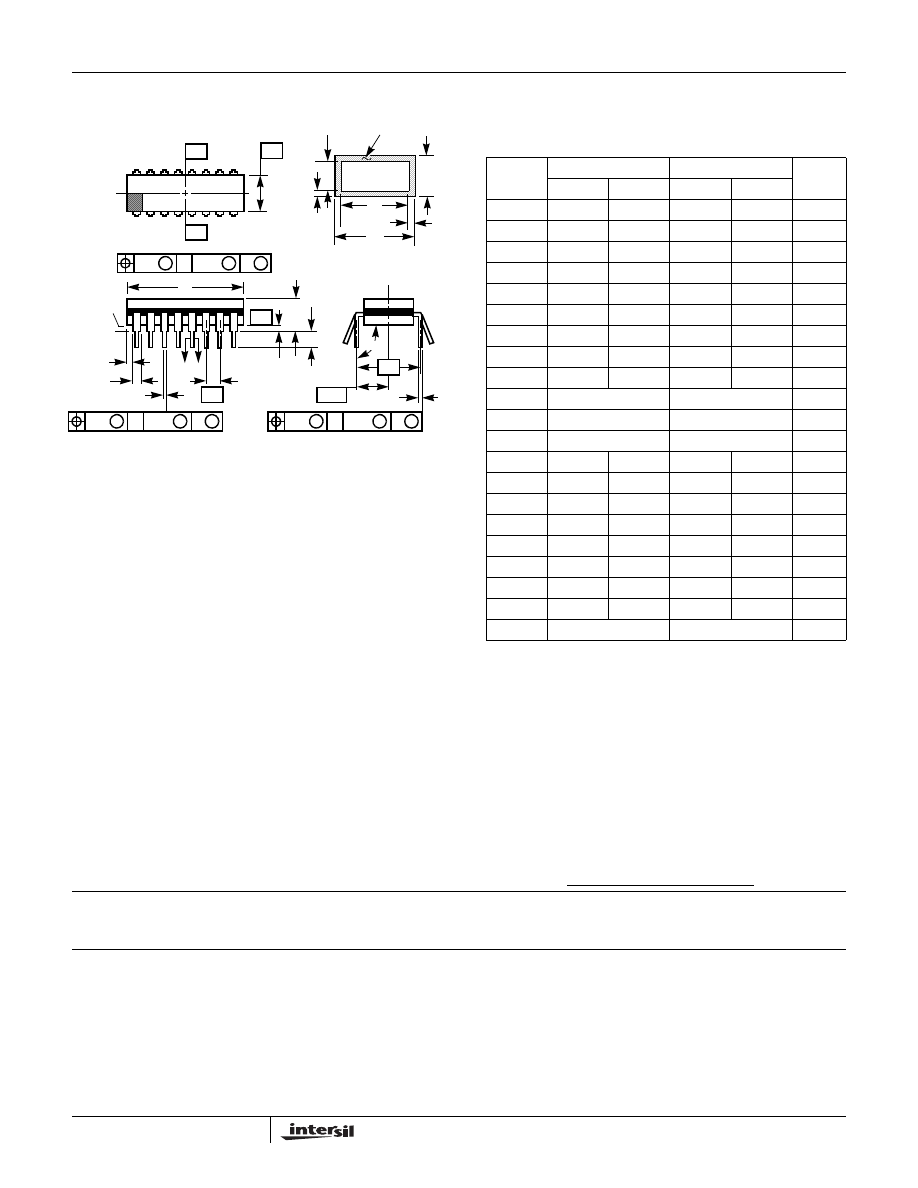

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

NOTES:

1. Index area: A notch or a pin one identification mark shall be locat-

ed adjacent to pin one and shall be located within the shaded

area shown. The manufacturerĺs identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

bbb

C A - B

S

c

Q

L

A

SEATING

BASE

D

PLANE

PLANE

-D-

-A-

-C-

-B-

α

D

E

S1

b2

b

A

e

M

c1

b1

(c)

(b)

SECTION A-A

BASE

LEAD FINISH

METAL

e

A/2

A

M

S

S

ccc

C A - B

M

D

S

S

aaa

C A - B

M

D

S

S

e

A

F14.3

MIL-STD-1835 GDIP1-T14 (D-1, CONFIGURATION A)

14 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.200

-

5.08

-

b

0.014

0.026

0.36

0.66

2

b1

0.014

0.023

0.36

0.58

3

b2

0.045

0.065

1.14

1.65

-

b3

0.023

0.045

0.58

1.14

4

c

0.008

0.018

0.20

0.46

2

c1

0.008

0.015

0.20

0.38

3

D

-

0.785

-

19.94

5

E

0.220

0.310

5.59

7.87

5

e

0.100 BSC

2.54 BSC

-

eA

0.300 BSC

7.62 BSC

-

eA/2

0.150 BSC

3.81 BSC

-

L

0.125

0.200

3.18

5.08

-

Q

0.015

0.060

0.38

1.52

6

S1

0.005

-

0.13

-

7

α

90

o

105

o

90

o

105

o

-

aaa

-

0.015

-

0.38

-

bbb

-

0.030

-

0.76

-

ccc

-

0.010

-

0.25

-

M

-

0.0015

-

0.038

2, 3

N

14

14

8

Rev. 0 4/94