| Secciones |

|---|

| Foros Electrónica |

|

|

| Boletines de correo |

|

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

LM12CL 80W Operational Amplifier

Check for Samples:

The turn-on characteristics are controlled by keeping

1

FEATURES

the output open-circuited until the total supply voltage

2

Input Protection

reaches 14V. The output is also opened as the case

Controlled Turn On

temperature exceeds 150 °C or as the supply voltage

approaches the BV

CEO

of the output transistors. The

Thermal Limiting

IC withstands overvoltages to 80V.

Overvoltage Shutdown

This monolithic op amp is compensated for unity-gain

Output-Current Limiting

feedback, with a small-signal bandwidth of 700 kHz.

Dynamic Safe-Area Protection

Slew rate is 9V/

μ

s, even as a follower. Distortion and

capacitive-load stability rival that of the best designs

DESCRIPTION

using complementary output transistors. Further, the

The LM12 is a power op amp capable of driving ±25V

IC withstands large differential input voltages and is

at ±10A while operating from ±30V supplies. The

well behaved should the common-mode range be

monolithic IC can deliver 80W of sine wave power

exceeded.

into

a

4

Ω

load

with

0.01%

distortion.

Power

The LM12 establishes that monolithic ICs can deliver

bandwidth is 60 kHz. Further, a peak dissipation

considerable

output

power

without

resorting

to

capability of 800W allows it to handle reactive loads

complex

switching

schemes.

Devices

can

be

such as transducers, actuators or small motors

paralleled

or

bridged

for

even

greater

output

without derating. Important features include:

capability. Applications include operational power

The IC delivers ±10A output current at any output

supplies, high-voltage regulators, high-quality audio

voltage yet is completely protected against overloads,

amplifiers, tape-head positioners, x-y plotters or other

including shorts to the supplies. The dynamic safe-

servo-control systems.

area protection is provided by instantaneous peak-

The LM12 is supplied in a four-lead, TO-220 package

temperature limiting within the power transistor array.

with V

-

on the case. A gold-eutectic die-attach to a

molybdenum interface is used to avoid thermal

fatigue problems. The LM12 is specified for either

military or commercial temperature range.

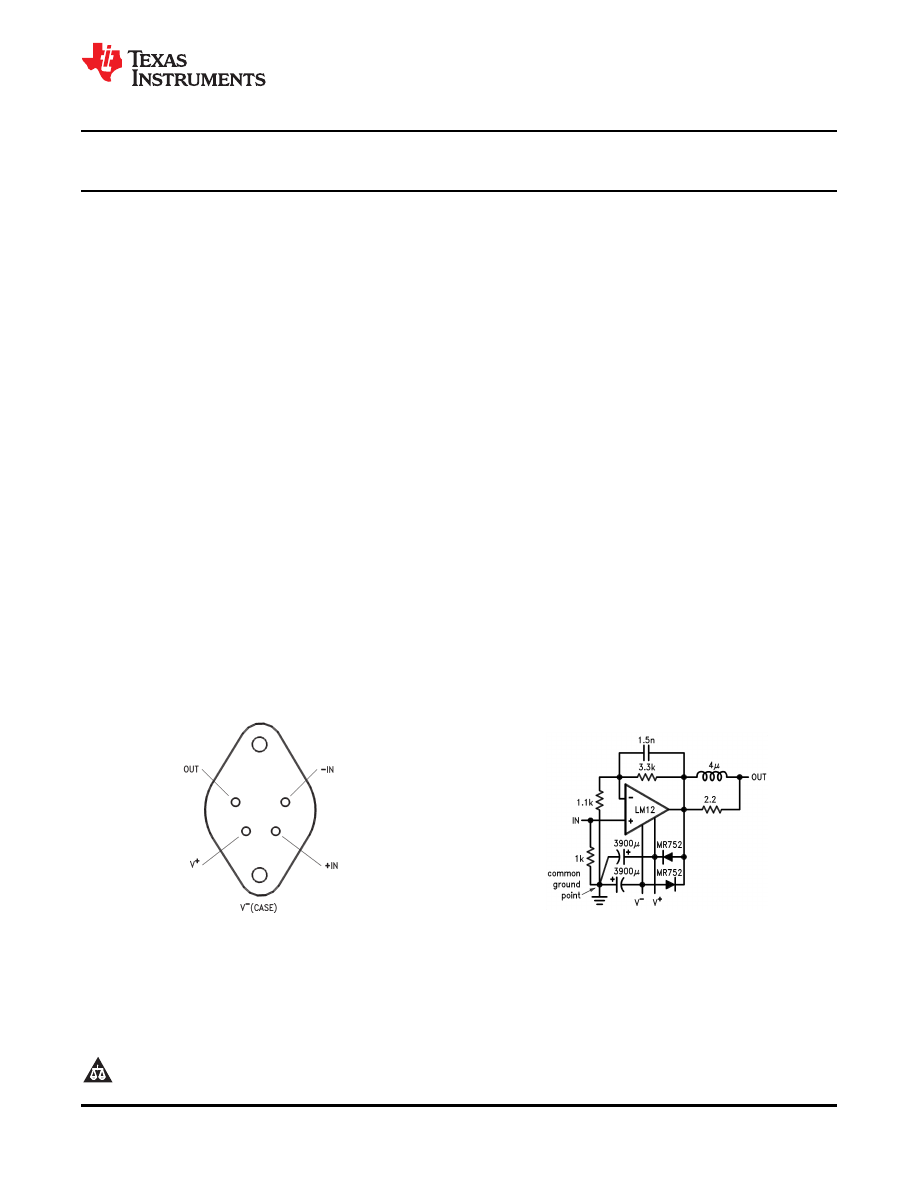

Connection Diagram

Typical Application*

*Low distortion (0.01%) audio amplifier

4-pin glass epoxy TO-3

socket is available from

Figure 1.

AUGAT INC.

Part number 8112-AG7

TO-220

Bottom View

See Package Number NEP

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Copyright © 1999-2013, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

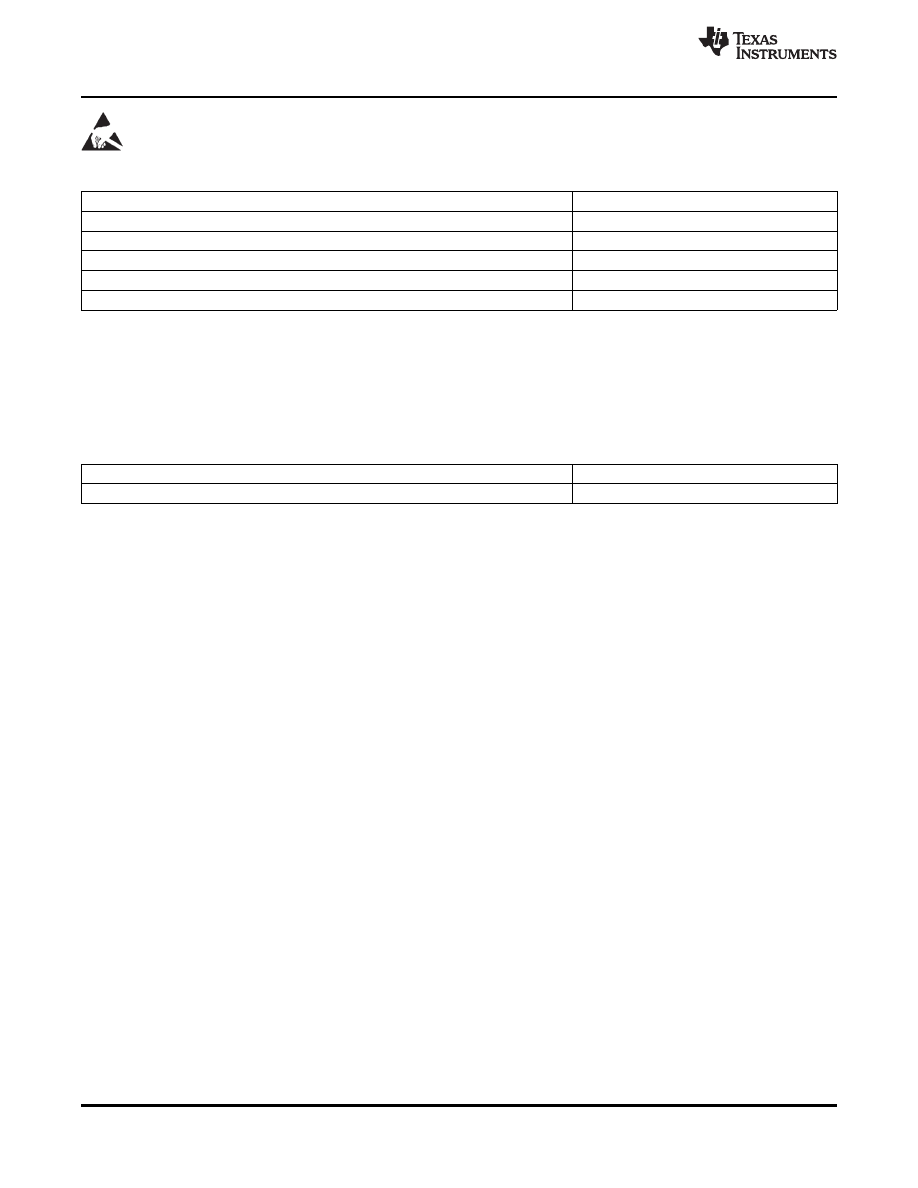

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

Absolute Maximum Ratings

(1) (2)

Total Supply Voltage

(1)

80V

Input Voltage

See

(3)

Output Current

Internally Limited

Junction Temperature

See

(4)

Storage Temperature Range

-

65 °C to 150 °C

Lead Temperature (Soldering, 10 seconds)

300 °C

(1)

Absolute maximum ratings indicate limits beyond which damage to the device may occur. The maximum voltage for which the LM12 is

ensured to operate is given in the operating ratings and in Note 4. With inductive loads or output shorts, other restrictions described in

applications section apply.

(2)

If Military/Aerospace specified devices are required, please contact the Texas Instruments Sales Office/Distributors for availability and

specifications.

(3)

Neither input should exceed the supply voltage by more than 50 volts nor should the voltage between one input and any other terminal

exceed 60 volts.

(4)

Operating junction temperature is internally limited near 225 °C within the power transistor and 160 °C for the control circuitry.

Operating Ratings

Total Supply Voltage

15V to 60V

Case Temperature

(1)

0 °C to 70 °C

(1)

The supply voltage is ±30V (V

MAX

= 60V), unless otherwise specified. The voltage across the conducting output transistor (supply to

output) is V

DISS

and internal power dissipation is P

DISS

. Temperature range is 0 °C

≤

T

C

≤

70 °C where T

C

is the case temperature.

Standard typeface indicates limits at 25 °C while boldface type refers to limits or special conditions over full temperature range.

With no heat sink, the package will heat at a rate of 35 °C/sec per 100W of internal dissipation.

2

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

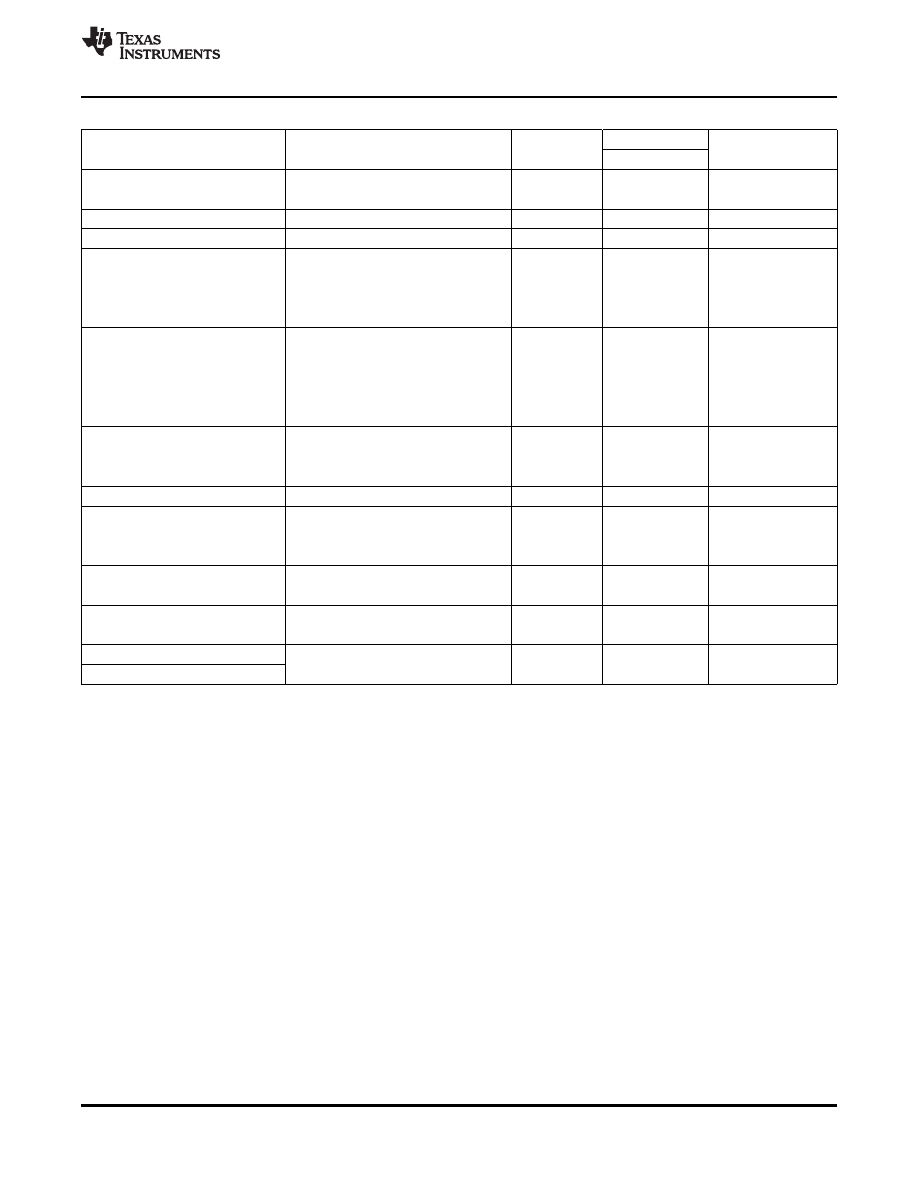

Electrical Characteristics

(1)

LM12CL

Typ

Parameter

Conditions

Units

25 °C

Limits

Input Offset Voltage

±10V

≤

V

S

≤

±0.5 V

MAX

, V

CM

= 0

2

15/20

mV (max)

Input Bias Current

V

-

+ 4V

≤

V

CM

≤

V+

-

2V

0.15

0.7/1.0

μ

A (max)

Input Offset Current

V

-

+4V

≤

V

CM

≤

V+

-

2V

0.03

0.2/0.3

μ

A (max)

Common Mode Rejection

V

-

+4V

≤

V

CM

≤

V+

-

2V

86

70/65

dB (min)

Power Supply Rejection

V+ = 0.5 V

MAX

,

90

70/65

dB (min)

-

6V

≥

V

- ≥ -

0.5 V

MAX

V

-

=

-

0.5 V

MAX

,

110

75/70

dB (min)

6V

≤

V+

≤

0.5 V

MAX

Output Saturation Threshold

t

ON

= 1 ms,

Δ

V

IN

= 5 (10 ) mV,

I

OUT

= 1A

1.8

2.2/2.5

V (max)

8A

4

5/7

V (max)

10A

5

V (max)

Large Signal Voltage Gain

t

ON

= 2 ms,

V

SAT

= 2V, I

OUT

= 0

100

30/20

V/mV (min)

V

SAT

= 8V, R

L

= 4

Ω

50

15/10

V/mV (min)

Thermal Gradient Feedback

P

DISS

= 50W, t

ON

= 65 ms

30

100

μ

V/W (max)

Output-Current Limit

t

ON

= 10 ms, V

DISS

= 10V

13

16

A (max)

t

ON

= 100 ms, V

DISS

= 58V

1.5

0.9/0.6

A (min)

1.5

1.7

A (max)

Power Dissipation Rating

t

ON

= 100 ms, V

DISS

= 20V

100

80/55

W (min)

V

DISS

= 58V

80

52/35

W (min)

DC Thermal Resistance

See

(2)

V

DISS

= 20V

2.3

2.9

°C/W (max)

V

DISS

= 58V

2.7

4.5

°C/W (max)

AC Thermal Resistance

See

(2)

1.6

2.1

°C/W (max)

Supply Current

V

OUT

= 0, I

OUT

= 0

60

120/140

mA (max)

(1)

The supply voltage is ±30V (V

MAX

= 60V), unless otherwise specified. The voltage across the conducting output transistor (supply to

output) is V

DISS

and internal power dissipation is P

DISS

. Temperature range is 0 °C

≤

T

C

≤

70 °C where T

C

is the case temperature.

Standard typeface indicates limits at 25 °C while boldface type refers to limits or special conditions over full temperature range.

With no heat sink, the package will heat at a rate of 35 °C/sec per 100W of internal dissipation.

(2)

This thermal resistance is based upon a peak temperature of 200 °C in the center of the power transistor and a case temperature of

25 °C measured at the center of the package bottom. The maximum junction temperature of the control circuitry can be estimated based

upon a dc thermal resistance of 0.9 °C/W or an ac thermal resistance of 0.6 °C/W for any operating voltage.

Copyright © 1999-2013, Texas Instruments Incorporated

3

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

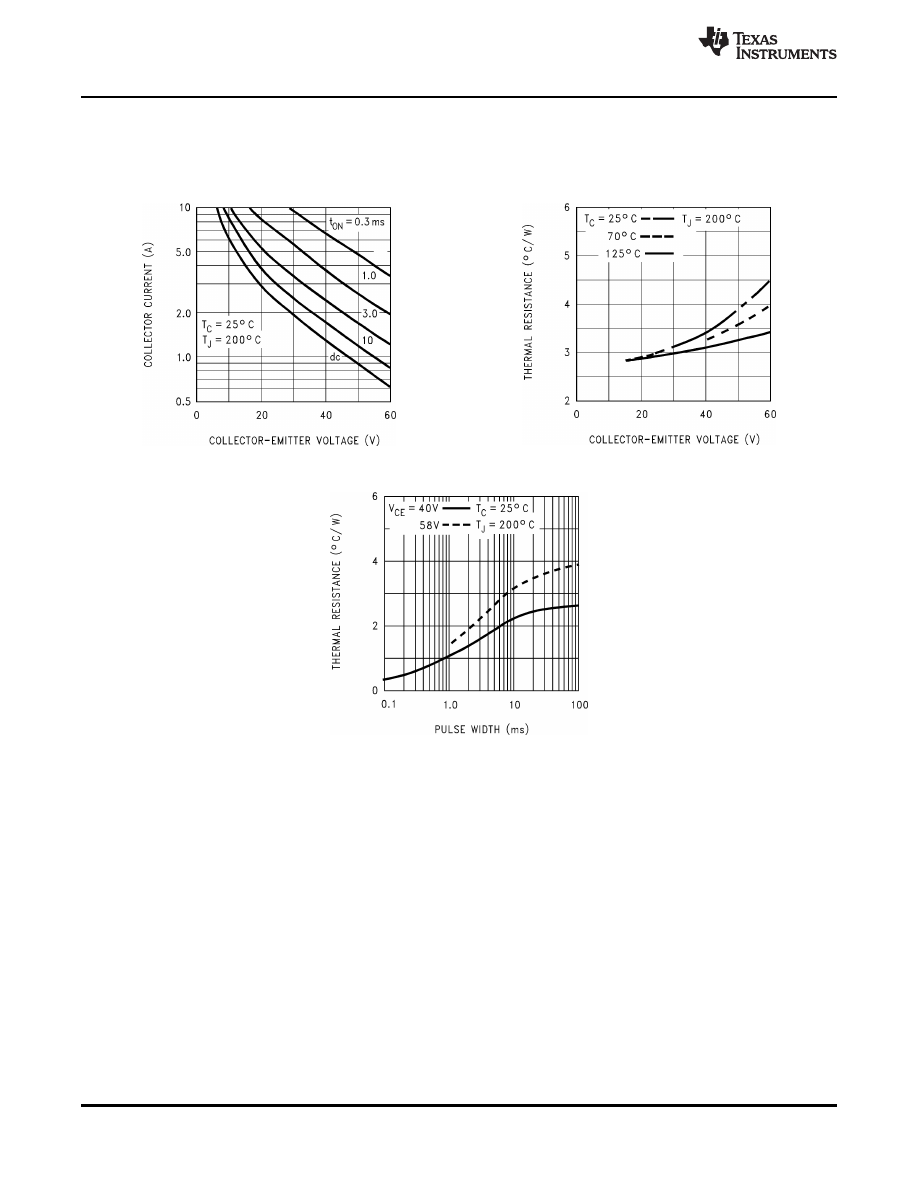

Output-Transistor Ratings (Ensured)

Although the output and supply leads are resistant to electrostatic discharges from handling, the input leads are not. The part

should be treated accordingly.

Safe Area

DC Thermal Resistance

Figure 2.

Figure 3.

Pulse Thermal Resistance

Figure 4.

4

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

Typical Performance Characteristics

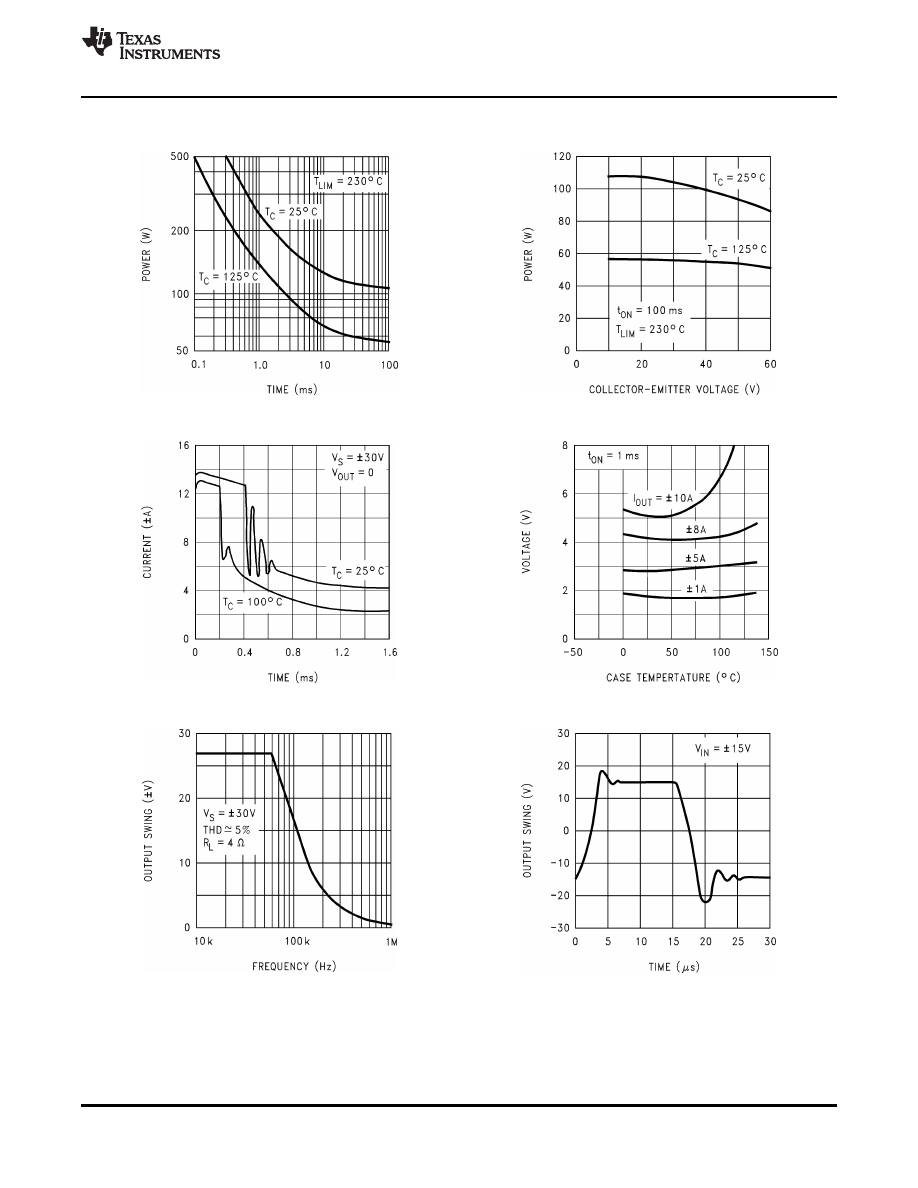

Pulse Power Limit

Pulse Power Limit

Figure 5.

Figure 6.

Peak Output Current

Output Saturation Voltage

Figure 7.

Figure 8.

Large Signal Response

Follower Pulse Response

Figure 9.

Figure 10.

Copyright © 1999-2013, Texas Instruments Incorporated

5

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

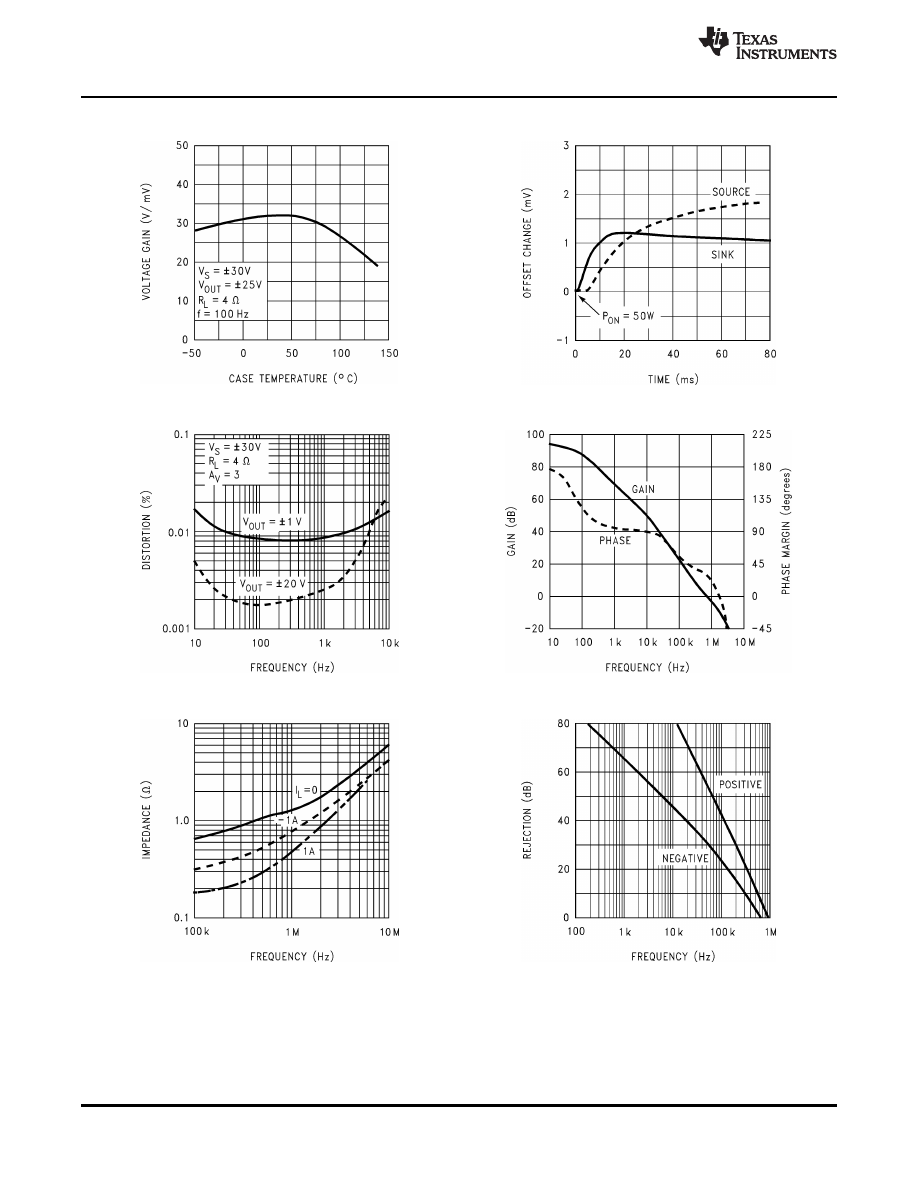

Typical Performance Characteristics (continued)

Large Signal Gain

Thermal Response

Figure 11.

Figure 12.

Total Harmonic Distortion

Frequency Response

Figure 13.

Figure 14.

Output Impedance

Power Supply Rejection

Figure 15.

Figure 16.

6

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

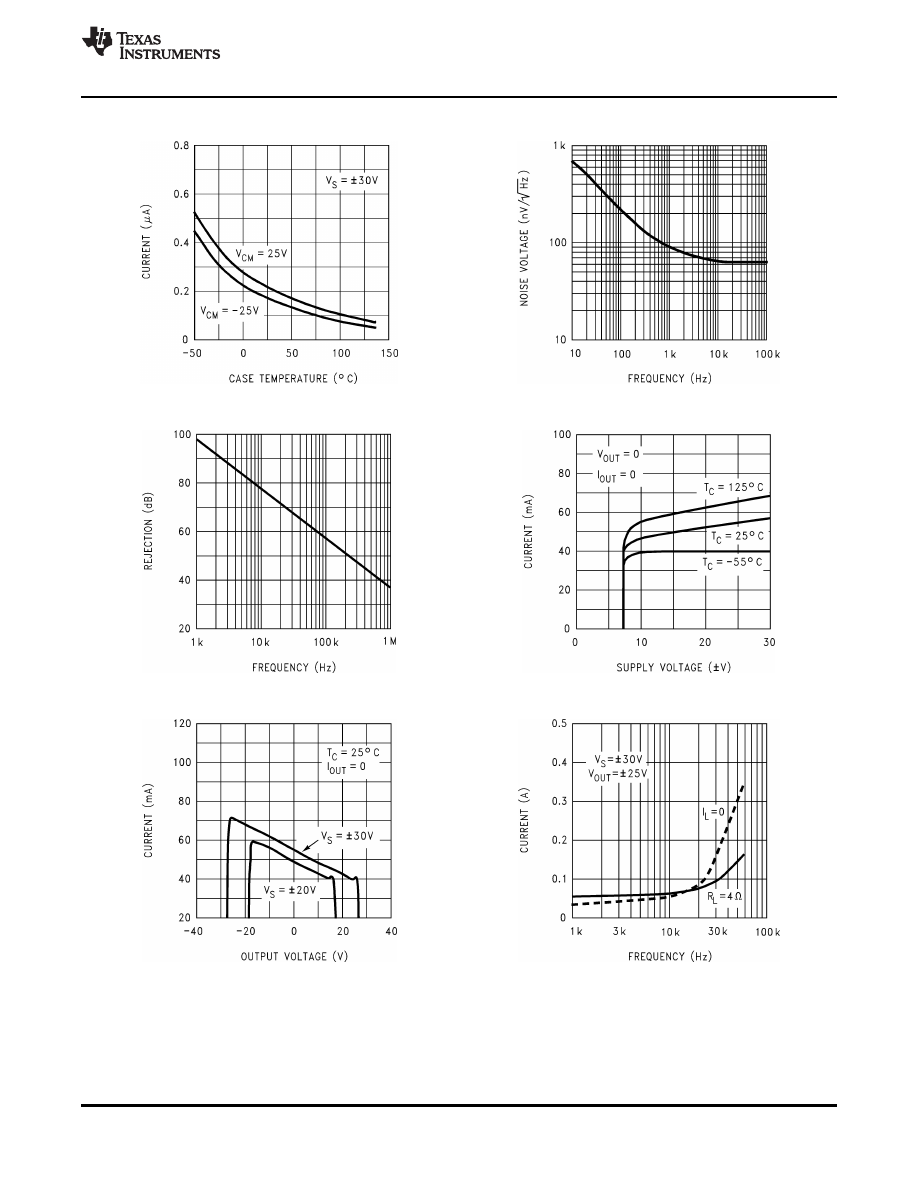

Typical Performance Characteristics (continued)

Input Bias Current

Input Noise Voltage

Figure 17.

Figure 18.

Common Mode Rejection

Supply Current

Figure 19.

Figure 20.

Supply Current

Cross-Supply Current

Figure 21.

Figure 22.

Copyright © 1999-2013, Texas Instruments Incorporated

7

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

APPLICATION INFORMATION

GENERAL

Twenty five years ago the operational amplifier was a specialized design tool used primarily for analog

computation. However, the availability of low cost IC op amps in the late 1960's prompted their use in rather

mundane applications, replacing a few discrete components. Once a few basic principles are mastered, op amps

can be used to give exceptionally good results in a wide range of applications while minimizing both cost and

design effort.

The availability of a monolithic power op amp now promises to extend these advantages to high-power designs.

Some conventional applications are given here to illustrate op amp design principles as they relate to power

circuitry. The inevitable fall in prices, as the economies of volume production are realized, will prompt their use in

applications that might now seem trivial. Replacing single power transistors with an op amp will become

economical because of improved performance, simplification of attendant circuitry, vastly improved fault

protection, greater reliability and the reduction of design time.

Power op amps introduce new factors into the design equation. With current transients above 10A, both the

inductance and resistance of wire interconnects become important in a number of ways. Further, power ratings

are a crucial factor in determining performance. But the power capability of the IC cannot be realized unless it is

properly mounted to an adequate heat sink. Thus, thermal design is of major importance with power op amps.

This application summary starts off by identifying the origin of strange problems observed while using the LM12

in a wide variety of designs with all sorts of fault conditions. A few simple precautions will eliminate these

problems. One would do well to read the section on supply bypassing, lead inductance, output clamp

diodes, ground loops and reactive loading before doing any experimentation. Should there be problems

with erratic operation, blow-outs, excessive distortion or oscillation, another look at these sections is in

order.

The management and protection circuitry can also affect operation. Should the total supply voltage exceed

ratings or drop below 15-20V, the op amp shuts off completely. Case temperatures above 150 °C also cause

shut down until the temperature drops to 145 °C. This may take several seconds, depending on the thermal

system. Activation of the dynamic safe-area protection causes both the main feedback loop to lose control and a

reduction in output power, with possible oscillations. In ac applications, the dynamic protection will cause

waveform distortion. Since the LM12 is well protected against thermal overloads, the suggestions for determining

power dissipation and heat sink requirements are presented last.

SUPPLY BYPASSING

All op amps should have their supply leads bypassed with low-inductance capacitors having short leads and

located close to the package terminals to avoid spurious oscillation problems. Power op amps require larger

bypass capacitors. The LM12 is stable with good-quality electrolytic bypass capacitors greater than 20

μ

F. Other

considerations may require larger capacitors.

The current in the supply leads is a rectified component of the load current. If adequate bypassing is not

provided, this distorted signal can be fed back into internal circuitry. Low distortion at high frequencies requires

that the supplies be bypassed with 470

μ

F or more, at the package terminals.

LEAD INDUCTANCE

With ordinary op amps, lead-inductance problems are usually restricted to supply bypassing. Power op amps are

also sensitive to inductance in the output lead, particularly with heavy capacitive loading. Feedback to the input

should be taken directly from the output terminal, minimizing common inductance with the load. Sensing to a

remote load must be accompanied by a high-frequency feedback path directly from the output terminal. Lead

inductance can also cause voltage surges on the supplies. With long leads to the power source, energy stored in

the lead inductance when the output is shorted can be dumped back into the supply bypass capacitors when the

short is removed. The magnitude of this transient is reduced by increasing the size of the bypass capacitor near

the IC. With 20

μ

F local bypass, these voltage surges are important only if the lead length exceeds a couple feet

(> 1

μ

H lead inductance). Twisting together the supply and ground leads minimizes the effect.

8

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

GROUND LOOPS

With fast, high-current circuitry, all sorts of problems can arise from improper grounding. In general, difficulties

can be avoided by returning all grounds separately to a common point. Sometimes this is impractical. When

compromising, special attention should be paid to the ground returns for the supply bypasses, load and input

signal. Ground planes also help to provide proper grounding.

Many problems unrelated to system performance can be traced to the grounding of line-operated test equipment

used for system checkout. Hidden paths are particularly difficult to sort out when several pieces of test equipment

are used but can be minimized by using current probes or the new isolated oscilloscope pre-amplifiers.

Eliminating any direct ground connection between the signal generator and the oscilloscope synchronization

input solves one common problem.

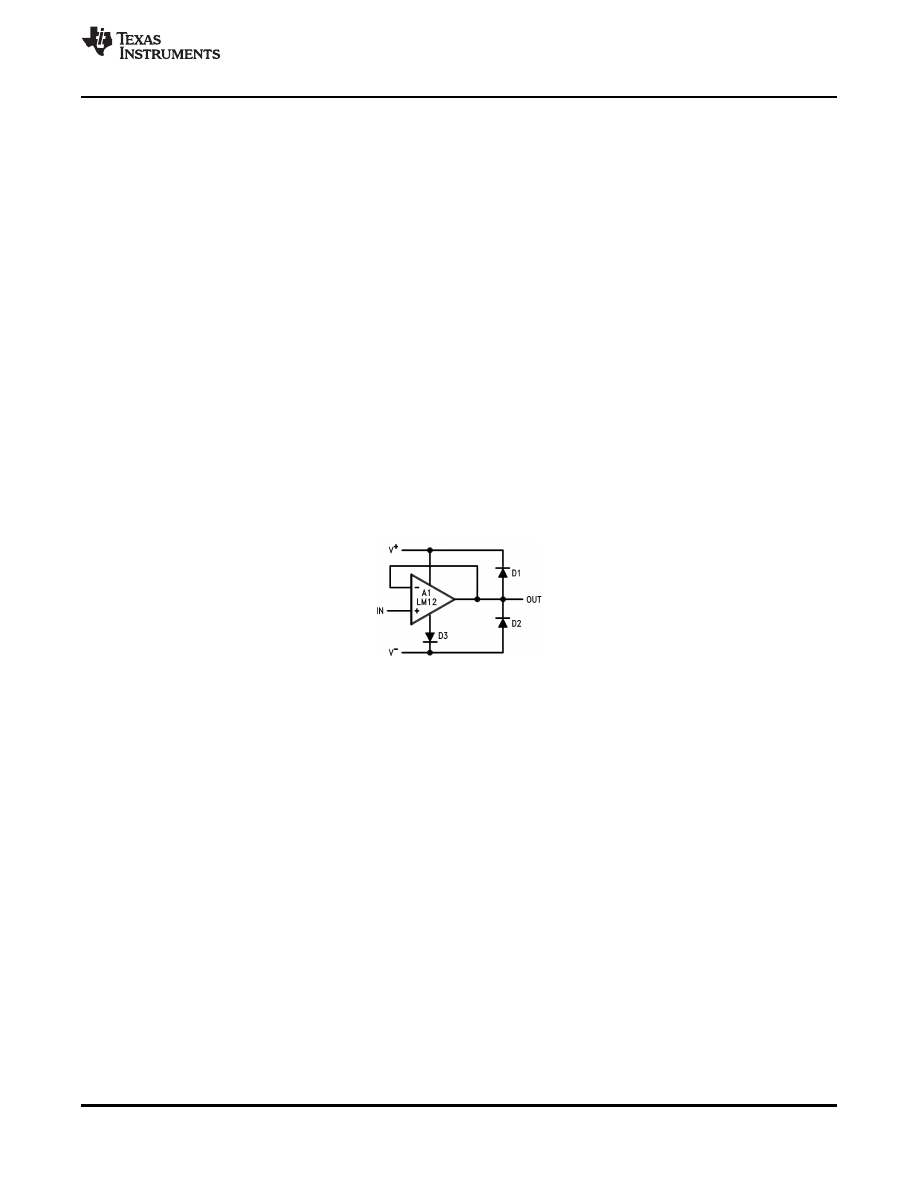

OUTPUT CLAMP DIODES

When a push-pull amplifier goes into power limit while driving an inductive load, the stored energy in the load

inductance can drive the output outside the supplies. Although the LM12 has internal clamp diodes that can

handle several amperes for a few milliseconds, extreme conditions can cause destruction of the IC. The internal

clamp diodes are imperfect in that about half the clamp current flows into the supply to which the output is

clamped while the other half flows across the supplies. Therefore, the use of external diodes to clamp the output

to the power supplies is strongly recommended. This is particularly important with higher supply voltages.

Experience has demonstrated that hard-wire shorting the output to the supplies can induce random failures if

these external clamp diodes are not used and the supply voltages are above ±20V. Therefore it is prudent to use

outputclamp diodes even when the load is not particularly inductive. This also applies to experimental setups in

that blowouts have been observed when diodes were not used. In packaged equipment, it may be possible to

eliminate these diodes, providing that fault conditions can be controlled.

Heat sinking of the clamp diodes is usually unimportant in that they only clamp current transients. Forward drop

with 15A fault transients is of greater concern. Usually, these transients die out rapidly. The clamp to the

negative supply can have somewhat reduced effectiveness under worst case conditions should the forward drop

exceed 1.0V. Mounting this diode to the power op amp heat sink improves the situation. Although the need has

only been demonstrated with some motor loads, including a third diode (D3 above) will eliminate any concern

about the clamp diodes. This diode, however, must be capable of dissipating continuous power as determined by

the negative supply current of the op amp.

Copyright © 1999-2013, Texas Instruments Incorporated

9

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

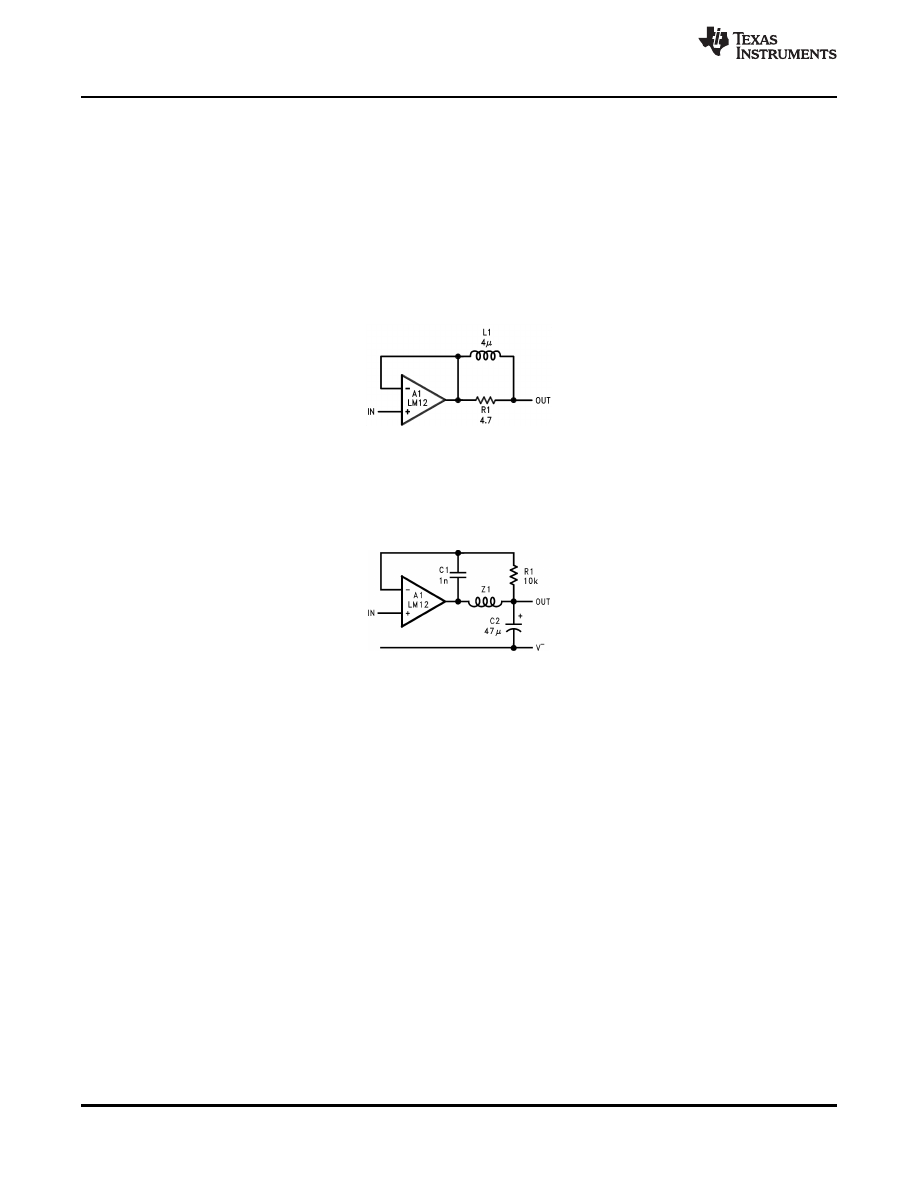

REACTIVE LOADING

The LM12 is normally stable with resistive, inductive or smaller capacitive loads. Larger capacitive loads interact

with the open-loop output resistance (about 1

Ω

) to reduce the phase margin of the feedback loop, ultimately

causing oscillation. The critical capacitance depends upon the feedback applied around the amplifier; a unity-gain

follower can handle about 0.01

μ

F, while more than 1

μ

F does not cause problems if the loop gain is ten. With

loop gains greater than unity, a speedup capacitor across the feedback resistor will aid stability. In all cases, the

op amp will behave predictably only if the supplies are properly bypassed, ground loops are controlled and high-

frequency feedback is derived directly from the output terminal, as recommended earlier.

So-called capacitive loads are not always capacitive. A high-Q capacitor in combination with long leads can

present a series-resonant load to the op amp. In practice, this is not usually a problem; but the situation should

be kept in mind.

Large capacitive loads (including series-resonant) can be accommodated by isolating the feedback amplifier from

the load as shown above. The inductor gives low output impedance at lower frequencies while providing an

isolating impedance at high frequencies. The resistor kills the Q of series resonant circuits formed by capacitive

loads. A low inductance, carbon-composition resistor is recommended. Optimum values of L and R depend upon

the feedback gain and expected nature of the load, but are not critical. A 4

μ

H inductor is obtained with 14 turns

of number 18 wire, close spaced, around a one-inch-diameter form.

The LM12 can be made stable for all loads with a large capacitor on the output, as shown above. This

compensation gives the lowest possible closed-loop output impedance at high frequencies and the best load-

transient response. It is appropriate for such applications as voltage regulators.

A feedback capacitor, C

1

, is connected directly to the output pin of the IC. The output capacitor, C

2

, is connected

at the output terminal with short leads. Single-point grounding to avoid dc and ac ground loops is advised.

The impedance, Z

1

, is the wire connecting the op amp output to the load capacitor. About 3-inches of number-18

wire (70 nH) gives good stability and 18-inches (400 nH) begins to degrade load-transient response. The

minimum load capacitance is 47

μ

F, if a solid-tantalum capacitor with an equivalent series resistance (ESR) of

0.1

Ω

is used. Electrolytic capacitors work as well, although capacitance may have to be increased to 200

μ

F to

bring ESR below 0.1

Ω

.

Loop stability is not the only concern when op amps are operated with reactive loads. With time-varying signals,

power dissipation can also increase markedly. This is particularly true with the combination of capacitive loads

and high-frequency excitation.

10

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

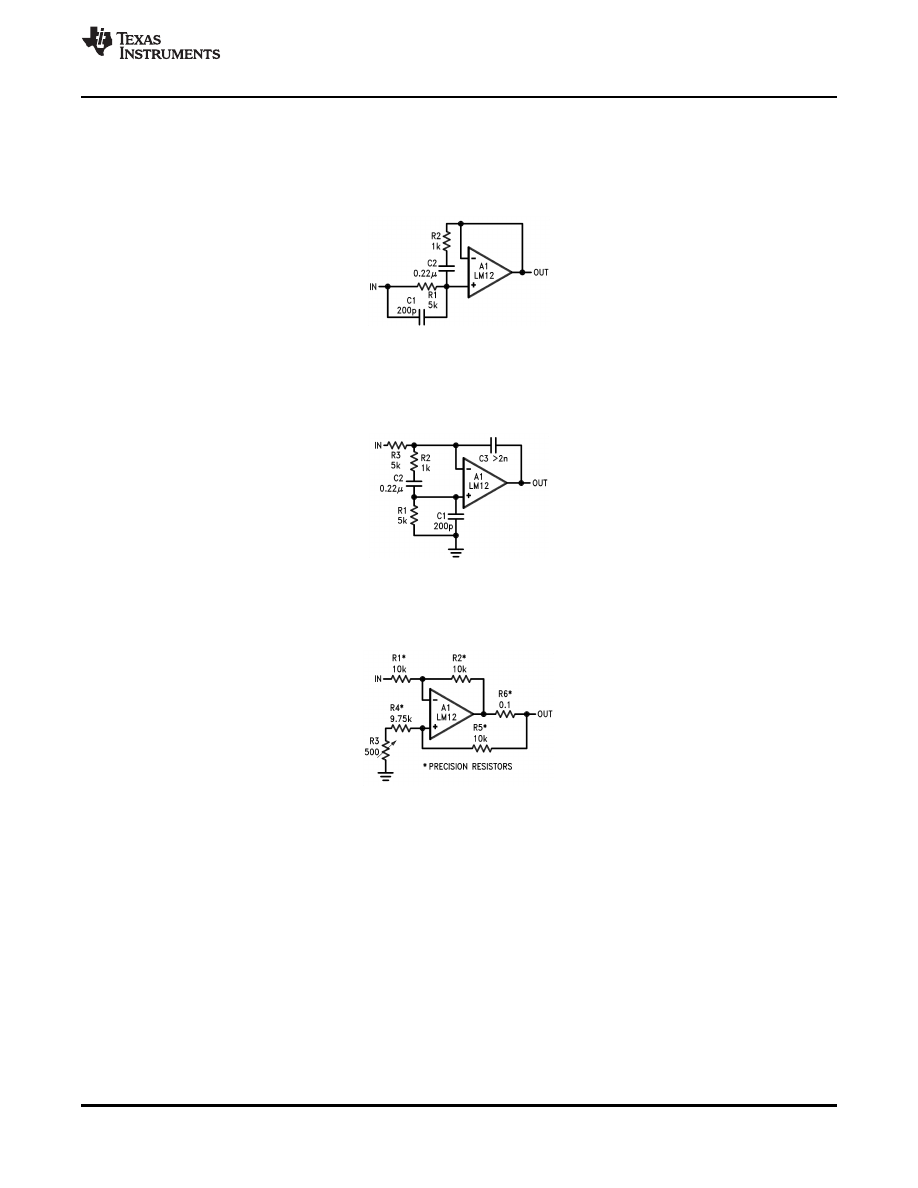

INPUT COMPENSATION

The LM12 is prone to low-amplitude oscillation bursts coming out of saturation if the high-frequency loop gain is

near unity. The voltage follower connection is most susceptible. This glitching can be eliminated at the expense

of small-signal bandwidth using input compensation. Input compensation can also be used in combination with

LR load isolation to improve capacitive load stability.

An example of a voltage follower with input compensation is shown here. The R

2

C

2

combination across the input

works with R

1

to reduce feedback at high frequencies without greatly affecting response below 100 kHz. A lead

capacitor, C

1

, improves phase margin at the unity-gain crossover frequency. Proper operation requires that the

output impedance of the circuitry driving the follower be well under 1 k

Ω

at frequencies up to a few hundred

kilohertz.

Extending input compensation to the integrator connection is shown here. Both the follower and this integrator

will handle 1

μ

F capacitive loading without LR output isolation.

CURRENT DRIVE

This circuit provides an output current proportional to the input voltage. Current drive is sometimes preferred for

servo motors because it aids in stabilizing the servo loop by reducing phase lag caused by motor inductance. In

applications requiring high output resistance, such as operational power supplies running in the current mode,

matching of the feedback resistors to 0.01% is required. Alternately, an adjustable resistor can be used for

trimming.

Copyright © 1999-2013, Texas Instruments Incorporated

11

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

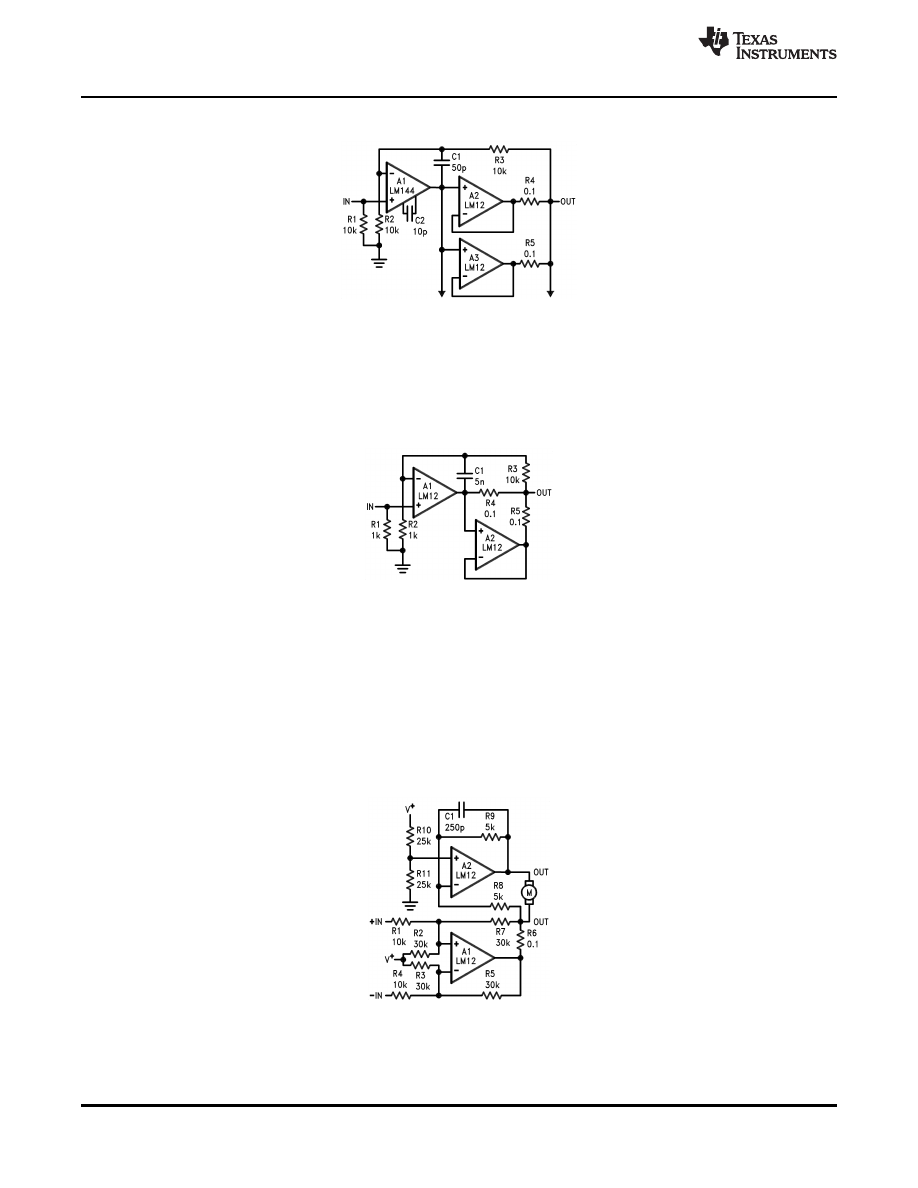

PARALLEL OPERATION

Output drive beyond the capability of one power amplifier can be provided as shown here. The power op amps

are wired as followers and connected in parallel with the outputs coupled through equalization resistors. A

standard, high-voltage op amp is used to provide voltage gain. Overall feedback compensates for the voltage

dropped across the equalization resistors.

With parallel operation, there may be an increase in unloaded supply current related to the offset voltage across

the equalization resistors. More output buffers, with individual equalization resistors, may be added to meet even

higher drive requirements.

This connection allows increased output capability without requiring a separate control amplifier. The output

buffer, A

2

, provides load current through R

5

equal to that supplied by the main amplifier, A

1

, through R

4

. Again,

more output buffers can be added.

Current sharing among paralleled amplifiers can be affected by gain error as the power-bandwidth limit is

approached. In the first circuit, the operating current increase will depend upon the matching of high-frequency

characteristics. In the second circuit, however, the entire input error of A

2

appears across R

4

and R

5

. The supply

current increase can cause power limiting to be activated as the slew limit is approached. This will not damage

the LM12. It can be avoided in both cases by connecting A

1

as an inverting amplifier and restricting bandwidth

with C

1

.

SINGLE-SUPPLY OPERATION

Although op amps are usually operated from dual supplies, single-supply operation is practical. This bridge

amplifier supplies bi-directional current drive to a servo motor while operating from a single positive supply. The

output is easily converted to voltage drive by shorting R

6

and connecting R

7

to the output of A

2

, rather than A

1

.

12

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

Either input may be grounded, with bi-directional drive provided to the other. It is also possible to connect one

input to a positive reference, with the input signal varying about this voltage. If the reference voltage is above 5V,

R

2

and R

3

are not required.

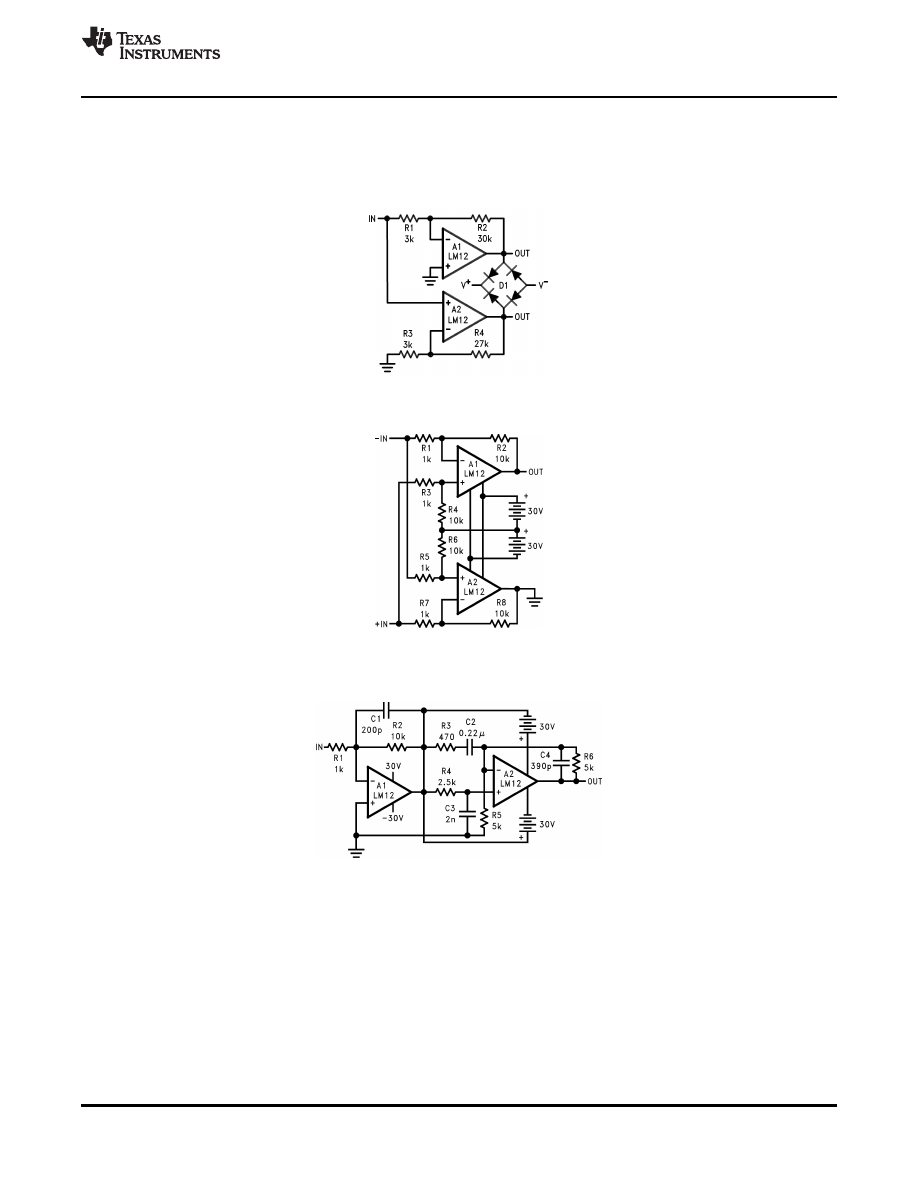

HIGH VOLTAGE AMPLIFIERS

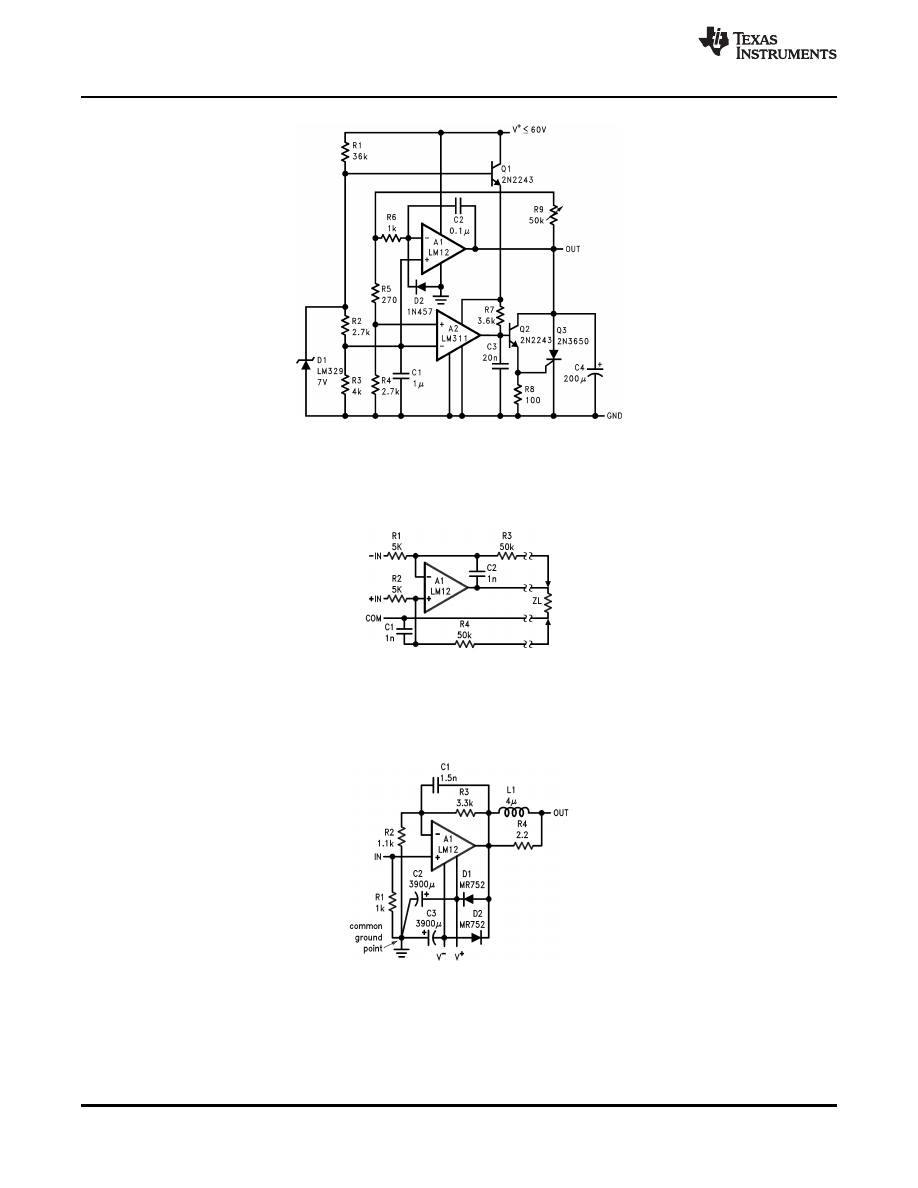

The voltage swing delivered to the load can be doubled by using the bridge connection shown here. Output

clamping to the supplies can be provided by using a bridge-rectifier assembly.

One limitation of the standard bridge connection is that the load cannot be returned to ground. This can be

circumvented by operating the bridge with floating supplies, as shown above. For single-ended drive, either input

can be grounded.

This circuit shows how two amplifiers can be cascaded to double output swing. The advantage over the bridge is

that the output can be increased with any number of stages, although separate supplies are required for each.

Copyright © 1999-2013, Texas Instruments Incorporated

13

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

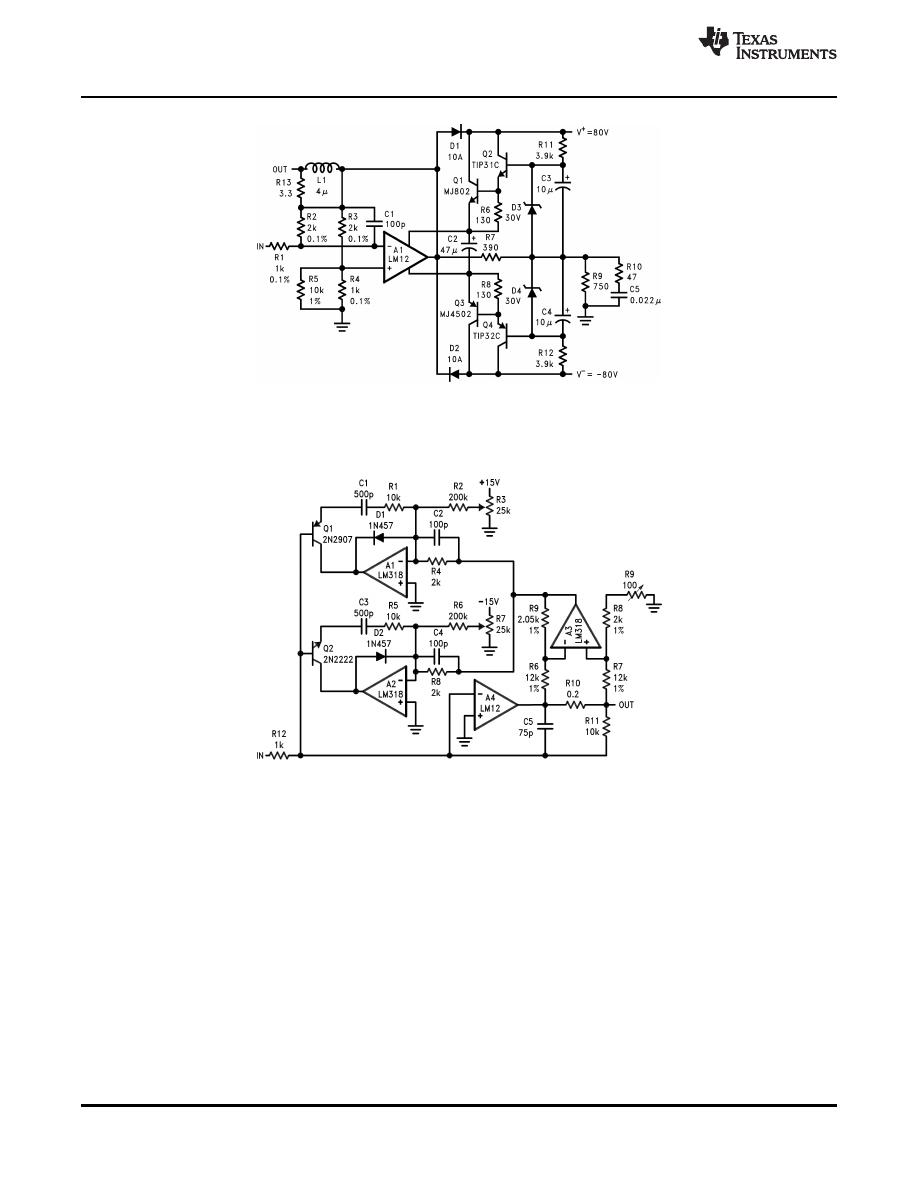

Discrete transistors can be used to increase output drive to ±70V at ±10A as shown above. With proper thermal

design, the IC will provide safe-area protection for the external transistors. Voltage gain is about thirty.

OPERATIONAL POWER SUPPLY

Note: Supply voltages for the LM318s are ±15V

External current limit can be provided for a power op amp as shown above. The positive and negative current

limits can be set precisely and independently. Fast response is assured by D

1

and D

2

. Adjustment range can be

set down to zero with potentiometers R

3

and R

7

. Alternately, the limit can be programmed from a voltage

supplied to R

2

and R

6

. This is the set up required for an operational power supply or voltage-programmable

power source.

14

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

SERVO AMPLIFIERS

When making servo systems with a power op amp, there is a temptation to use it for frequency shaping to

stabilize the servo loop. Sometimes this works; other times there are better ways; and occasionally it just doesn't

fly. Usually it's a matter of how quickly and to what accuracy the servo must stabilize.

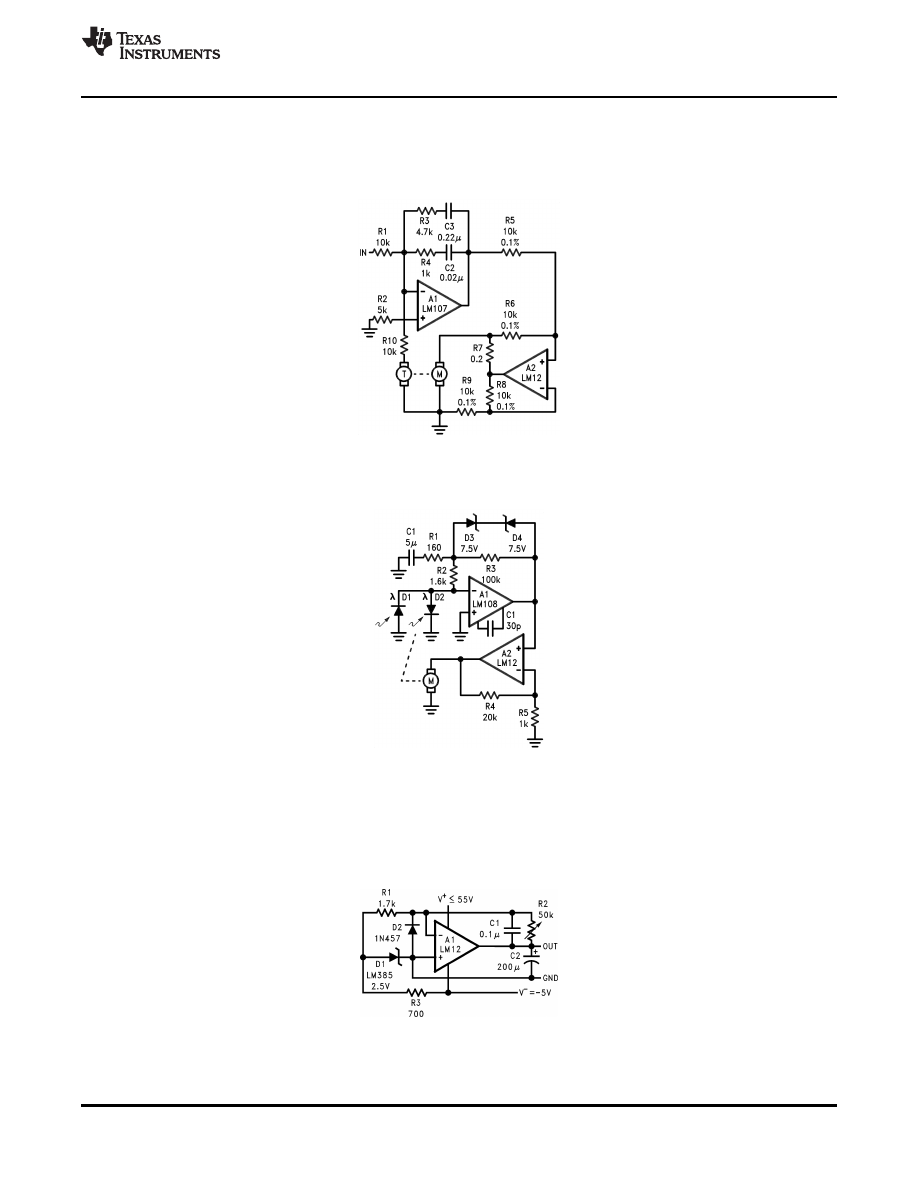

This motor/tachometer servo gives an output speed proportional to input voltage. A low-level op amp is used for

frequency shaping while the power op amp provides current drive to the motor. Current drive eliminates loop

phase shift due to motor inductance and makes high-performance servos easier to stabilize.

This position servo uses an op amp to develop the rate signal electrically instead of using a tachometer. In high-

performance servos, rate signals must be developed with large error signals well beyond saturation of the motor

drive. Using a separate op amp with a feedback clamp allows the rate signal to be developed properly with

position errors more than an order of magnitude beyond the loop-saturation level as long as the photodiode

sensors are positioned with this in mind.

VOLTAGE REGULATORS

An op amp can be used as a positive or negative regulator. Unlike most regulators, it can sink current to absorb

energy dumped back into the output. This positive regulator has a 0-50V output range.

Copyright © 1999-2013, Texas Instruments Incorporated

15

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

Dual supplies are not required to use an op amp as a voltage regulator if zero output is not required. This 4V to

50V regulator operates from a single supply. Should the op amp not be able to absorb enough energy to control

an overvoltage condition, a SCR will crowbar the output.

REMOTE SENSING

Remote sensing as shown above allows the op amp to correct for dc drops in cables connecting the load. Even

so, cable drop will affect transient response. Degradation can be minimized by using twisted, heavy-gauge wires

on the output line. Normally, common and one input are connected together at the sending end.

AUDIO AMPLIFIERS

A power amplifier suitable for use in high-quality audio equipment is shown above. Harmonic distortion is about

0.01-percent. Intermodulation distortion (60 Hz/7 kHz, 4:1) measured 0.015-percent. Transient response and

saturation recovery are clean, and the 9 V/

μ

s slew rate of the LM12 virtually eliminates transient intermodulation

distortion. Using separate amplifiers to drive low- and high-frequency speakers gets rid of high-level crossover

networks and attenuators. Further, it prevents clipping on the low-frequency channel from distorting the high

frequencies.

16

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

DETERMINING MAXIMUM DISSIPATION

It is a simple matter to establish power requirements for an op amp driving a resistive load at frequencies well

below 10 Hz. Maximum dissipation occurs when the output is at one-half the supply voltage with high-line

conditions. The individual output transistors must be rated to handle this power continuously at the maximum

expected case temperature. The power rating is limited by the maximum junction temperature as determined by

T

J

= T

C

+ P

DISS

Θ

JC

where

T

C

is the case temperature as measured at the center of the package bottom

P

DISS

is the maximum power dissipation

Θ

JC

is the thermal resistance at the operating voltage of the output transistor

(1)

Recommended maximum junction temperatures are 200 °C within the power transistor and 150 °C for the control

circuitry.

If there is ripple on the supply bus, it is valid to use the average value in worst-case calculations as long as the

peak rating of the power transistor is not exceeded at the ripple peak. With 120 Hz ripple, this is 1.5 times the

continuous power rating.

Dissipation requirements are not so easily established with time varying output signals, especially with reactive

loads. Both peak and continuous dissipation ratings must be taken into account, and these depend on the signal

waveform as well as load characteristics.

With a sine wave output, analysis is fairly straightforward. With supply voltages of ±V

S

, the maximum average

power dissipation of both output transistors is

where

Z

L

is the magnitude of the load impedance

Θ

its phase angle

(2)

Maximum average dissipation occurs below maximum output swing for

Θ

< 40 °.

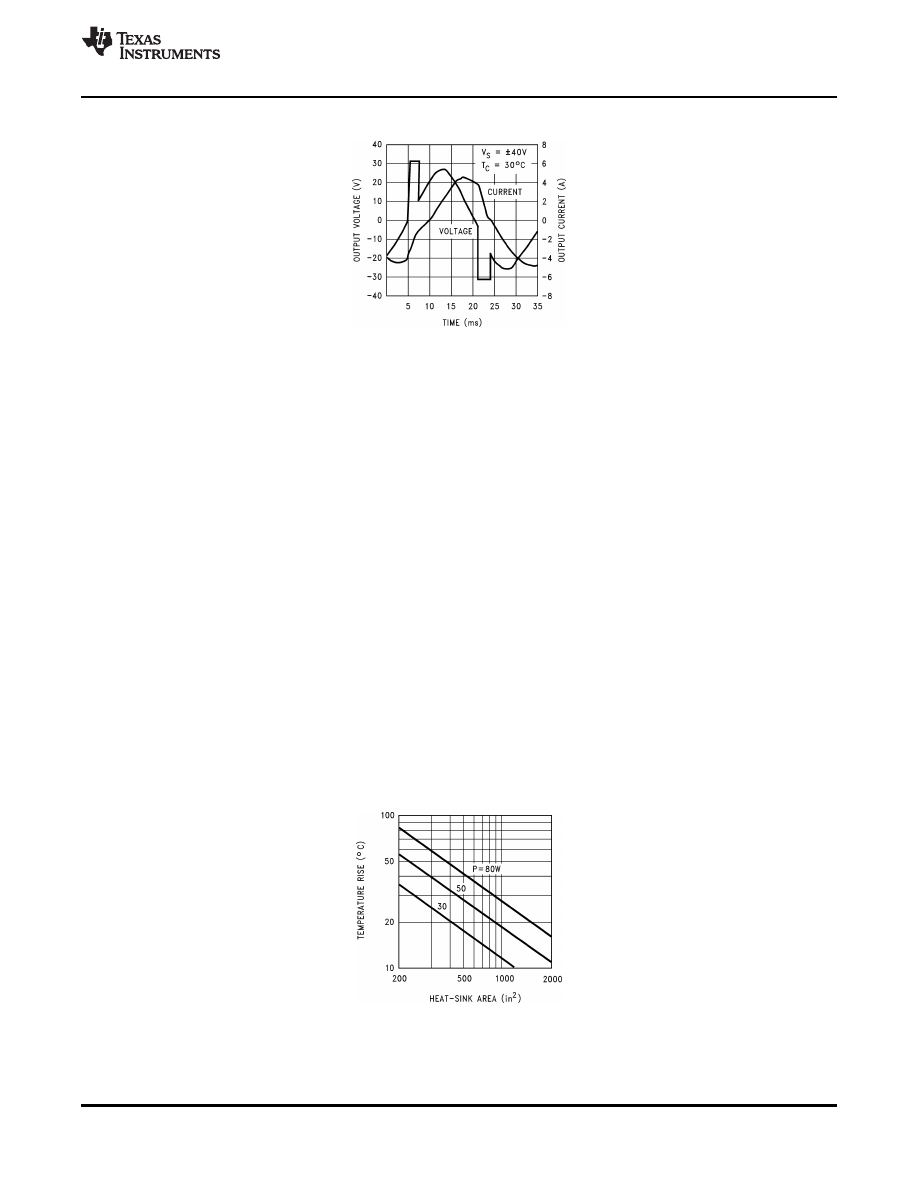

The instantaneous power dissipation over the conducting half cycle of one output transistor is shown here. Power

dissipation is near zero on the other half cycle. The output level is that resulting in maximum peak and average

dissipation. Plots are given for a resistive and a series RL load. The latter is representative of a 4

Ω

loudspeaker

operating below resonance and would be the worst case condition in most audio applications. The peak

dissipation of each transistor is about four times average. In ac applications, power capability is often limited by

the peak ratings of the power transistor.

Copyright © 1999-2013, Texas Instruments Incorporated

17

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

The pulse thermal resistance of the LM12 is specified for constant power pulse duration. Establishing an exact

equivalency between constant-power pulses and those encountered in practice is not easy. However, for sine

waves, reasonable estimates can be made at any frequency by assuming a constant power pulse amplitude

given by:

where

Ï

= 60 °

Θ

is the absolute value of the phase angle of Z

L

(3)

Equivalent pulse width is t

ON

0.4

Ï

for

Θ

= 0 and t

ON

0.2

Ï

for

Θ ≥

20 °, where

Ï

is the period of the output

waveform.

DISSIPATION DRIVING MOTORS

A motor with a locked rotor looks like an inductance in series with a resistance, for purposes of determining

driver dissipation. With slow-response servos, the maximum signal amplitude at frequencies where motor

inductance is significant can be so small that motor inductance does not have to be taken into account. If this is

the case, the motor can be treated as a simple, resistive load as long as the rotor speed is low enough that the

back emf is small by comparison to the supply voltage of the driver transistor.

A permanent-magnet motor can build up a back emf that is equal to the output swing of the op amp driving it.

Reversing this motor from full speed requires the output drive transistor to operate, initially, along a loadline

based upon the motor resistance and total supply voltage. Worst case, this loadline will have to be within the

continuous dissipation rating of the drive transistor; but system dynamics may permit taking advantage of the

higher pulse ratings. Motor inductance can cause added stress if system response is fast.

Shunt- and series-wound motors can generate back emf's that are considerably more than the total supply

voltage, resulting in even higher peak dissipation than a permanent-magnet motor having the same locked-rotor

resistance.

VOLTAGE REGULATOR DISSIPATION

The pass transistor dissipation of a voltage regulator is easily determined in the operating mode. Maximum

continuous dissipation occurs with high line voltage and maximum load current. As discussed earlier, ripple

voltage can be averaged if peak ratings are not exceeded; however, a higher average voltage will be required to

insure that the pass transistor does not saturate at the ripple minimum.

Conditions during start-up can be more complex. If the input voltage increases slowly such that the regulator

does not go into current limit charging output capacitance, there are no problems. If not, load capacitance and

load characteristics must be taken into account. This is also the case if automatic restart is required in recovering

from overloads.

Automatic restart or start-up with fast-rising input voltages cannot be ensured unless the continuous dissipation

rating of the pass transistor is adequate to supply the load current continuously at all voltages below the

regulated output voltage. In this regard, the LM12 performs much better than IC regulators using foldback current

limit, especially with high-line input voltage above 20V.

18

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

POWER LIMITING

Should the power ratings of the LM12 be exceeded, dynamic safe-area protection is activated. Waveforms with

this power limiting are shown for the LM12 driving ±26V at 30 Hz into 3

Ω

in series with 24 mH (

Θ

= 45 °). With an

inductive load, the output clamps to the supplies in power limit, as above. With resistive loads, the output voltage

drops in limit. Behavior with more complex RCL loads is between these extremes.

Secondary thermal limit is activated should the case temperature exceed 150 °C. This thermal limit shuts down

the IC completely (open output) until the case temperature drops to about 145 °C. Recovery may take several

seconds.

POWER SUPPLIES

Power op amps do not require regulated supplies. However, the worst-case output power is determined by the

low-line supply voltage in the ripple trough. The worst-case power dissipation is established by the average

supply voltage with high-line conditions. The loss in power output that can be ensured is the square of the ratio

of these two voltages.

Relatively simple off-line switching power supplies can provide voltage conversion, line isolation and 5-percent

regulation while reducing size and weight.

The regulation against ripple and line variations can provide a substantial increase in the power output that can

be specified under worst-case conditions. In addition, switching power supplies can convert low-voltage power

sources such as automotive batteries up to regulated, dual, high-voltage supplies optimized for powering power

op amps.

HEAT SINKING

A semiconductor manufacturer has no control over heat sink design. Temperature rating can only be based upon

case temperature as measured at the center of the package bottom. With power pulses of longer duration than

100 ms, case temperature is almost entirely dependent on heat sink design and the mounting of the IC to the

heat sink.

The design of heat sink is beyond the scope of this work. Convection-cooled heat sinks are available

commercially, and their manufacturers should be consulted for ratings. The preceding figure is a rough guide for

temperature rise as a function of fin area (both sides) available for convection cooling.

Copyright © 1999-2013, Texas Instruments Incorporated

19

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

Proper mounting of the IC is required to minimize the thermal drop between the package and the heat sink. The

heat sink must also have enough metal under the package to conduct heat from the center of the package

bottom to the fins without excessive temperature drop.

A thermal grease such as Wakefield type 120 or Thermalloy Thermacote should be used when mounting the

package to the heat sink. Without this compound, thermal resistance will be no better than 0.5 °C/W, and

probably much worse. With the compound, thermal resistance will be 0.2 °C/W or less, assuming under 0.005

inch combined flatness runout for the package and heat sink. Proper torquing of the mounting bolts is important.

Four to six inch-pounds is recommended.

Should it be necessary to isolate V

-

from the heat sink, an insulating washer is required. Hard washers like

berylium oxide, anodized aluminum and mica require the use of thermal compound on both faces. Two-mil mica

washers are most common, giving about 0.4 °C/W interface resistance with the compound. Silicone-rubber

washers are also available. A 0.5 °C/W thermal resistance is claimed without thermal compound. Experience has

shown that these rubber washers deteriorate and must be replaced should the IC be dismounted.

Isostrate insulating pads for four-lead TO-220 packages are available from Power Devices, Inc. Thermal grease

is not required, and the insulators should not be reused.

Definition of Terms

Input offset voltage: The absolute value of the voltage between the input terminals with the output voltage and

current at zero.

Input bias current: The absolute value of the average of the two input currents with the output voltage and

current at zero.

Input offset current: The absolute value of the difference in the two input currents with the output voltage and

current at zero.

Common-mode rejection: The ratio of the input voltage range to the change in offset voltage between the

extremes.

Supply-voltage rejection: The ratio of the specified supply-voltage change to the change in offset voltage

between the extremes.

Output saturation threshold: The output swing limit for a specified input drive beyond that required for zero

output. It is measured with respect to the supply to which the output is swinging.

Large signal voltage gain: The ratio of the output voltage swing to the differential input voltage required to

drive the output from zero to either swing limit. The output swing limit is the supply voltage less a specified

quasi-saturation voltage. A pulse of short enough duration to minimize thermal effects is used as a

measurement signal.

Thermal gradient feedback: The input offset voltage change caused by thermal gradients generated by

heating of the output transistors, but not the package. This effect is delayed by several milliseconds and

results in increased gain error below 100 Hz.

Output-current limit: The output current with a fixed output voltage and a large input overdrive. The limiting

current drops with time once the protection circuitry is activated.

Power dissipation rating: The power that can be dissipated for a specified time interval without activating the

protection circuitry. For time intervals in excess of 100 ms, dissipation capability is determined by heat

sinking of the IC package rather than by the IC itself.

Thermal resistance: The peak, junction-temperature rise, per unit of internal power dissipation, above the case

temperature as measured at the center of the package bottom. The dc thermal resistance applies when

one output transistor is operating continuously. The ac thermal resistance applies with the output

transistors conducting alternately at a high enough frequency that the peak capability of neither transistor

is exceeded.

Supply current: The current required from the power source to operate the amplifier with the output voltage

and current at zero.

20

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

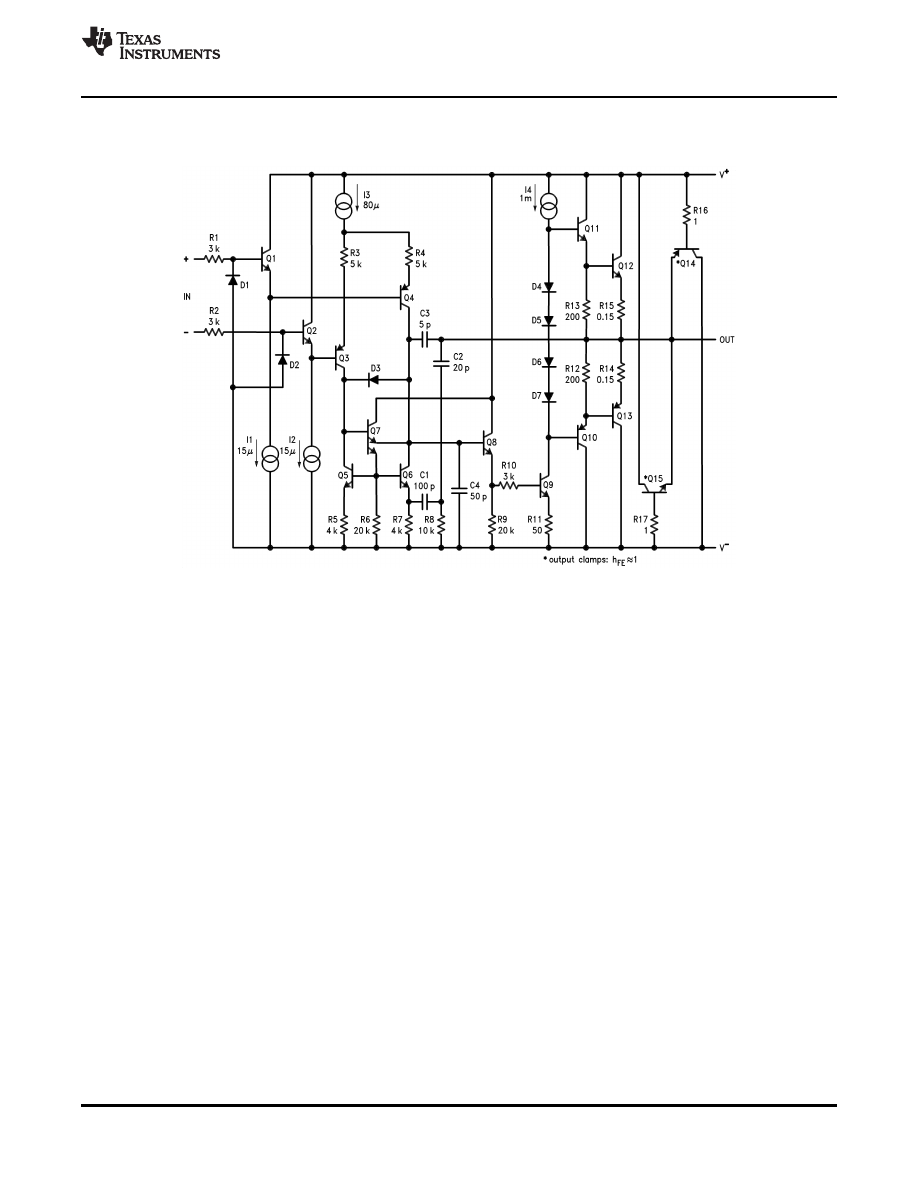

Equivalent Schematic

(excluding active protection circuitry)

Copyright © 1999-2013, Texas Instruments Incorporated

21

Product Folder Links:

OBSOLETE

SNOSBY8D - MAY 1999 - REVISED APRIL 2013

REVISION HISTORY

Changes from Revision C (April 2013) to Revision D

Page

Changed layout of National Data Sheet to TI format ..........................................................................................................

22

Copyright © 1999-2013, Texas Instruments Incorporated

Product Folder Links:

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as components) are sold subject to TIs terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TIs terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TIs goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or enhanced plastic are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products

Applications

Audio

Automotive and Transportation

Amplifiers

Communications and Telecom

Data Converters

Computers and Peripherals

DLP ® Products

Consumer Electronics

DSP

Energy and Lighting

Clocks and Timers

Industrial

Interface

Medical

Logic

Security

Power Mgmt

Space, Avionics and Defense

Microcontrollers

Video and Imaging

RFID

OMAP Applications Processors

TI E2E Community

Wireless Connectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Document Outline